-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the competitive world of mining and aggregate production, understanding the best Gyratory Crusher Wear Parts is crucial for longevity. Industry expert John Smith, a renowned mechanical engineer, emphasizes, "Choosing the right wear parts can significantly extend the life of your crusher." His insight highlights a common issue faced by operators: wear parts often fail to meet expected service life.

The choice of materials and design significantly influences performance. High-quality Gyratory Crusher Wear Parts can withstand intense pressure and abrasive materials. However, many operators underestimate the importance of regular maintenance and timely replacements. A common oversight is ignoring wear indicators, which can lead to unexpected downtimes and costly repairs.

Moreover, the market offers various options, but not all are created equal. Some wear parts may seem appealing due to lower costs, yet they can compromise performance and longevity. Striking a balance between cost and quality is essential. Mindful choices can lead to enhanced productivity and reduced operational headaches.

Gyratory crushers play a crucial role in the mining industry. They help reduce large rocks into smaller, manageable pieces. This process enhances ore recovery and improves efficiency. According to a recent industry report, these crushers account for nearly 30% of worldwide mining equipment. Their design enables continuous operation; however, wear parts can significantly affect performance.

Understanding the importance of wear parts is essential for longevity. The high operational temperatures and pressures create stress on these components. Regular monitoring can prevent unexpected failures. Utilizing quality wear parts can extend the lifespan of the machinery, ensuring consistent productivity. Often, operators overlook the impact of choosing the right materials for these parts.

Tips: Check wear indicators regularly. Implement predictive maintenance schedules. Evaluate parts based on wear patterns to optimize replacements. This approach could reduce downtime and increase output. While many operations invest heavily in machinery, neglecting wear parts can lead to costly repairs. Reflecting on maintenance strategies is vital for achieving operational excellence.

When it comes to the longevity of gyratory crusher wear parts, several factors play a crucial role. The material used for these parts significantly influences their life span. High-quality steel alloys offer great resistance to wear and tear. However, even the best materials can fail if not properly maintained. Regular inspections and timely replacements are key.

One important factor is the operating environment. Dust and debris can accelerate wear on parts. This means that working in a cleaner setting can lead to longer-lasting components. Moreover, aligning the crusher correctly promotes better performance and reduces unnecessary strain on the wear parts.

Tips for extending longevity: Regularly monitor wear patterns. Check for any misalignments. Keep the crushing area clean. These steps can save time and money in the long run. Remember, investing in good practices ensures that even average-quality parts can perform well.

Gyratory crushers are essential in mining and aggregates. They rely on wear parts to maintain efficiency. Key wear parts include concaves, mantles, and liners. Each part plays a critical role in crushing materials effectively.

Concaves are the stationary part inside the crusher. They wear down gradually as materials pass through. Choosing the right material can extend their life. Mantles, on the other hand, are the moving part that crushes rocks. Like concaves, they should be made from durable materials. If not, frequent replacements become a costly issue.

Liners protect the outer shell of the crusher. They face continuous impact, which leads to wear. Selecting appropriate liners can significantly reduce downtime. Many operators overlook this aspect. It’s essential to monitor wear patterns closely for effective maintenance. With the right approach, wear part longevity can be optimized.

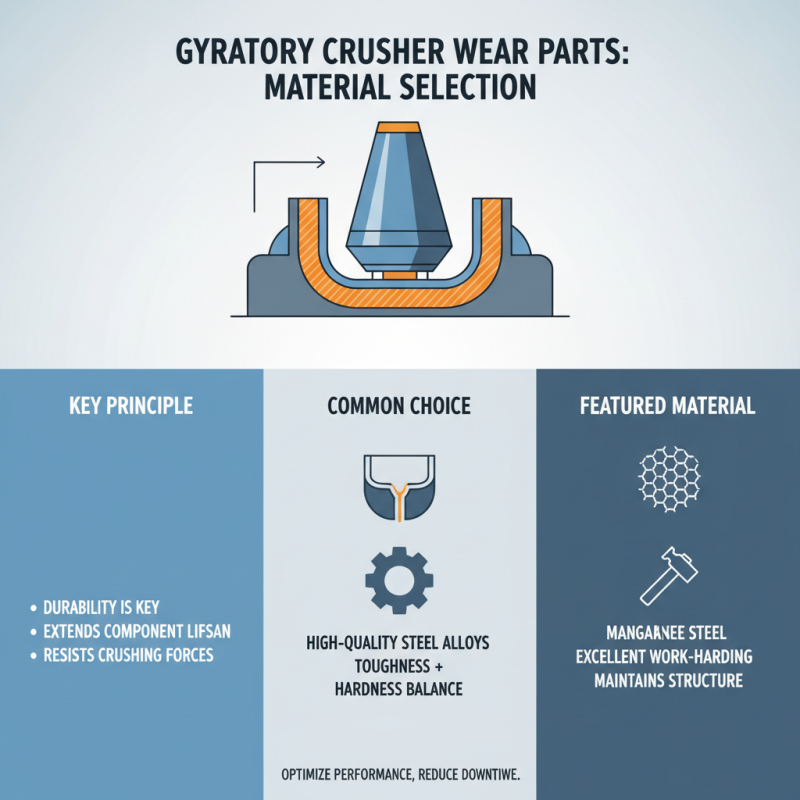

When choosing materials for gyratory crusher wear parts, durability is key. Selecting the right materials can significantly extend the lifespan of these components. High-quality steel alloys are common choices, as they offer a good balance of toughness and hardness. Manganese steel, for example, is known for its excellent work-hardening ability. It can withstand crushing forces while maintaining its structure.

Another critical aspect is the thickness of the wear parts. Thicker components can often provide better resistance to wear, but they can also increase the overall weight of the machine. This trade-off requires careful consideration. There’s also the challenge of finding materials that can endure extreme temperatures and pressures without cracking. Recycling old parts can be tempting, but it often leads to inconsistent quality and unexpected failures.

Furthermore, the application of a protective coating can enhance durability. Coatings serve as an additional barrier against wear and corrosion. However, not all coatings are created equal. Their effectiveness can vary based on several factors, such as the operating environment. Some operators overlook this detail, leading to premature wear and costly downtime. It’s essential to continuously evaluate the material choices and consider innovative solutions to improve longevity.

Gyratory crushers are essential for various industries. However, wear parts often experience immense stress and require regular maintenance. Proper maintenance can significantly extend their lifespan. According to recent industry reports, implementing effective maintenance strategies can reduce replacement costs by up to 30%.

One critical practice is regular inspection of wear parts. This includes checking the mantle and concave for signs of wear. Operators should change these parts before they reach their limit. Neglecting this can lead to catastrophic failures. Statistics show that preventative maintenance can increase operational efficiency by 15%.

Tip: Schedule weekly inspections to catch issues early.

Another important aspect is lubrication. Proper lubrication reduces friction, which can wear down components quicker. Monitoring lubrication levels can extend the life of the bushings and bearings. Keeping a consistent lubrication schedule maintains optimal performance.

Tip: Use high-quality lubricants recommended for gyratory crushers.

Training staff is vital. Even experienced operators can overlook small details. Workshops and training sessions keep everyone updated on maintenance best practices. Engagement in maintenance can foster a culture focused on longevity and reliability.

Tip: Consider monthly training refreshers for your team.

| Wear Part | Material | Typical Lifespan (Hours) | Maintenance Practices | Replacement Frequency |

|---|---|---|---|---|

| Mantle | High-Manganese Steel | 1,800 - 2,500 | Regular Inspection; Proper Lubrication | Every 6-12 months |

| Concave | Alloy Steel | 1,500 - 2,000 | Periodic Checking; Adjustment of Gaps | Every 6-12 months |

| Spider Cap | Cast Steel | 2,000 - 3,000 | Visual Inspection; Tightening Bolts | Annually |

| Shield | Wear-Resistant Steel | 1,000 - 1,500 | Regular Checks; Replacement for Damage | Every 3-6 months |