Vertical mill vibration greatly affects production!

Vertical mill vibration greatly affects production! Analysis of 3 kinds of causes of vibration of vertical mill and 5 kinds of control measures

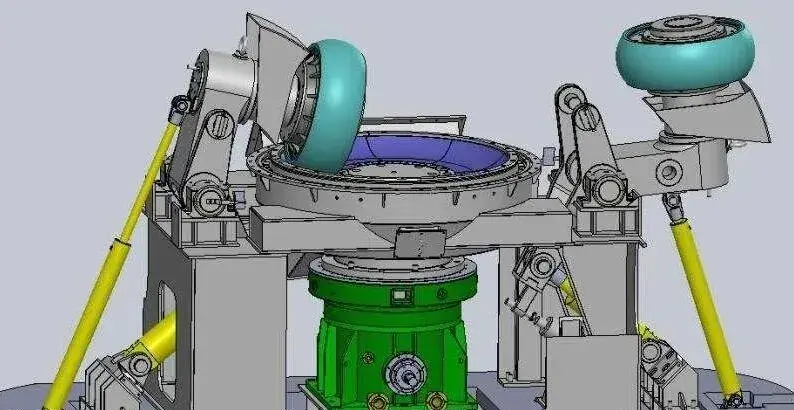

With the continuous innovation of technology, vertical mill began to be applied to cement raw material grinding, and because of its high efficiency and energy saving, vertical mill grinding technology has been rapidly promoted. Efficient equipment operation rate is the premise of ensuring production and efficiency. The vibration of vertical mill has great influence on the operating rate of equipment and directly affects the production. This paper shares the causes and control measures of vertical mill vibration.

1 Analysis of vibration causes of vertical mill

There are many reasons for vertical mill vibration, which can be summarized into three categories: process, equipment and electrical system.

1.1 Process control

Process control has a great influence on the vibration of the opposite mill. The vibration of most discrete mills is caused by unstable process control and uneven thickness of the material layer. When the material layer is thin, the grinding material can be less, the vertical mill work efficiency is low, and the material layer is too thin, so that there is rigid contact between the grinding roll and the grinding disc, causing greater vibration. Rigid contact will also accelerate the wear of the roller and the disk, resulting in higher energy consumption. On the contrary, when the material layer is too thick, the grinding capacity of the vertical mill is reduced, the equipment cycle load is increased, which is easy to cause the roller fluctuation, and severe vibration will occur.

1.2 Mechanical Factors

Common mechanical factors are mainly caused by problems with equipment quality and installation quality. The main reasons for the vibration of vertical mill are: the roller liner and the grinding disc are not firmly installed; The horizontal error between the base and the foundation of the reducer exceeds the specified range; Stop ring installation is not in place; The tensile rod will produce deviation after long time operation, resulting in uneven force.

1.3 Electrical Factors

During the operation of vertical mill, data monitoring and information feedback can be carried out by the control system. According to the feedback information, the central control operator and the field equipment personnel can adjust the relevant data and equipment control adjustment of the system. However, if the feedback data of the rotary measuring instrument or vibration measuring instrument is distorted or even damaged, the system can not be monitored or the feedback value is wrong, which affects the operation of the system.

2 Measures to control vibration of vertical mill

2.1 Feeding operation

When the water content of the feed material in the mill is high, the inlet cold air door should be closed, and the outlet temperature of the humidifying tower should be increased until the pressure difference in the mill reaches the standard value. When the material layer is too thin, the feeding amount should be increased, the pressure difference of the equipment should be increased, the material layer should be stabilized, and the vibration of the equipment should be reduced. If the material layer is too thick, the feeding amount should be reduced immediately and the ventilation amount increased to ensure the smooth discharge system. Keep the vertical abrasive layer stable at all times to avoid equipment vibration.

2.2 Grinding pressure adjustment

The central control operator should pay attention to the grinding pressure feedback value in time. When the grinding pressure is lower than the set pressure, nitrogen should be immediately filled to increase the grinding pressure. The balance between the three stretching rods should be ensured during the operation of the equipment. The imbalance between the stretching rods will lead to the increase of the vibration of the equipment, and may also lead to the fracture of the stretching rods in serious cases. Therefore, the tension force of the stretching rods should be adjusted in time to maintain the balance between the stretching rods.

2.3 Material thickness control

When the grinding pressure is fixed, if the retaining ring is set too high, the pressure difference in the grinding will increase and the material layer will be thicker. On the contrary, if the retaining ring is set too low, it is difficult to produce a fixed material layer thickness; The operator should adjust the height of the retaining ring according to the actual situation and maintain the stability of the thickness of the material layer. In addition, the scraping plate may break or even fall off during the operation of the equipment, resulting in the interruption of the material return work in the mill, and the accumulation of raw materials in the mill makes the material layer too thick. At this time, the scraper should be repaired and replaced in time.

2.4 Granularity control of grinding materials

Under the premise that the speed of the grinding disk is maintained unchanged, the larger the material particle size, the greater the centrifugal force, the more material is accumulated in the outer ring of the grinding disk, and the thinner the inner ring material, at this time, the grinding efficiency of the vertical mill is reduced, and it is easy to produce vibration. The operator should reduce the air volume in the mill and reduce the outlet temperature. If the particle size of the grinding material is too small, under the action of the separator, a large number of materials float in the mill, causing the material on the mill disk to be too thin, and then cause vibration, at this time should increase the amount of water in the mill, reduce the speed of the separator.

2.5 Avoid foreign matter entering the production process Site operators should always pay attention to avoid foreign matter entering the equipment, the broken debris of the air guide blade or the tool left by the repair personnel will cause abnormal sound and even vibration of the vertical mill. Field personnel should always pay attention to the operating status of the equipment, and clean up the abnormal sound in time. If the volume of the metal foreign body in the mill is small, the mill roller can be lifted and cleaned from the feed inlet; However, if the foreign body is too large, it must stop grinding and open the grinding door for cleaning. Vertical mill vibration seriously affects the life of the equipment, reduce the equipment operating rate, production can start from the process, machinery, electrical system and other aspects, find the problem timely treatment, as far as possible to avoid the vibration of the equipment. In addition to summarizing the above reasons, it is necessary to strengthen the maintenance and safety inspection of the equipment in production to ensure that the vertical mill has a stable and safe operating environment.