-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

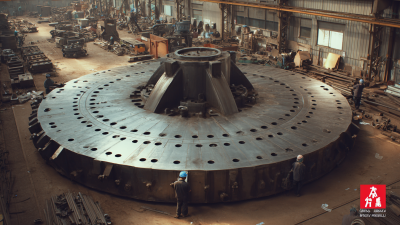

Understanding the intricacies of Gyratory Crusher Parts is key to maximizing the performance of these colossal machines in various industries, including mining and construction. As one of the most crucial components in the crushing process, gyratory crushers are known for their ability to handle large volumes of material, allowing for impressive efficiency and output. According to a recent report by Allied Market Research, the global mining equipment market is projected to reach $200 billion by 2027, with a significant share attributed to the use of advanced crushing technologies. This underscores the importance of not only selecting the right equipment but also maintaining a keen understanding of the parts that drive their performance.

The operational lifespan and reliability of gyratory crushers heavily depend on their componentry, including the mantle, concave, and other wear parts. Industry studies suggest that proper maintenance and understanding of these Gyratory Crusher Parts can lead to efficiency improvements of up to 30%. This essential knowledge not only helps to minimize unplanned downtimes but also enhances the predictive maintenance strategies that are becoming increasingly vital in today's data-driven industrial environment. Adopting a comprehensive approach to understanding these parts ensures that operators can achieve not only optimal performance but also cost savings in long-term operations.

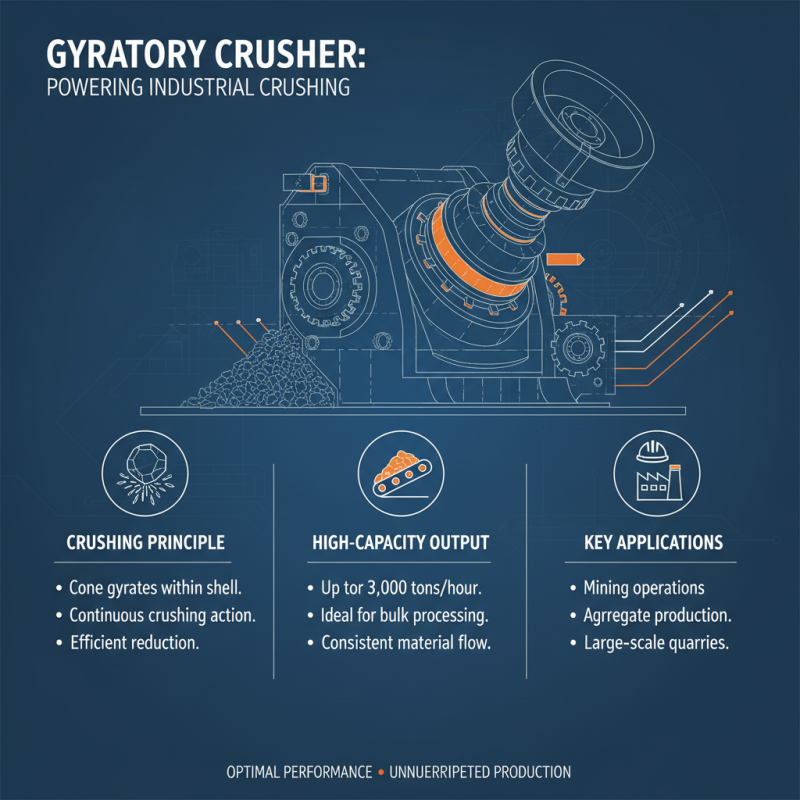

Gyratory crushers play a pivotal role in various industries, particularly in mining and aggregate production. Understanding the functionality of these machines is crucial for achieving optimal performance. Gyratory crushers operate on a unique principle where the crushing action is achieved through the gyration of a cone within a larger shell. This design allows for a more effective and continuous crushing process compared to traditional jaw crushers. Studies indicate that gyratory crushers can deliver a throughput of up to 3,000 tons per hour, making them suitable for high-capacity applications.

The primary components of a gyratory crusher include the mantle, bowl liner, and the eccentric mechanism. Each part serves a specific function in the crushing process. The mantle's movement, driven by the eccentric, creates a gap between the mantle and the bowl liner that decreases over time, effectively crushing the material. Additionally, advanced designs, such as those utilizing hydraulic systems for adjusting the product size and implementing wear-resistant materials, have significantly improved overall efficiency and lifespan of the equipment. According to industry reports, proper maintenance and a thorough understanding of these parts can lead to a reduction in operational downtime by as much as 25%, ultimately enhancing productivity in the long run.

Understanding the key components of gyratory crushers is crucial for ensuring their optimal performance in various industrial applications. At the heart of a gyratory crusher is the mantle, which is a crucial rotating element that initiates the crushing action. The mantle's design and material significantly influence the crusher's efficiency and wear resistance. According to a report from the Mining and Aggregates industry, the durability and performance of the mantle can impact the overall lifespan of the crushing unit by up to 20%, underscoring its critical role in maximizing productivity.

Another essential component is the concave, which surrounds the mantle and aids in the crushing process by providing a space for the material to be crushed. The shape and surface texture of the concave are designed for optimal fragmentation of materials, ensuring that the crushing action is efficient. Industry studies have shown that optimizing the concave design can enhance the throughput of a gyratory crusher by 15%, leading to more effective processing of raw materials. Additionally, the spider and the main shaft are critical for providing structural support and maintaining the alignment of the crushing components, making their integrity vital for preventing operational issues. Proper maintenance and understanding of these parts can significantly reduce downtime and improve overall operational efficiency.

The design of gyratory crushers significantly influences their operational performance, affecting not only efficiency but also the longevity of the machinery. According to a study published in the “Mining Engineering” journal, a well-engineered crusher design can lead to a 20-30% improvement in throughput compared to poorly designed models. Factors such as the angle of the crushing chamber, the size and shape of the mantle, and the crusher's overall structural integrity play a pivotal role in determining how effectively material is processed.

Moreover, advancements in design technology have enabled the development of crushers that are better equipped to handle varying types of materials and operating conditions. For instance, a report from the “International Journal of Mineral Processing” highlights that modern gyratory crushers incorporate enhanced geometries that allow for more uniform material flow, resulting in reduced wear and tear on components. This optimized material handling not only extends the lifespan of the machine but also translates into more consistent product quality, crucial for meeting industry specifications. Understanding these design elements is essential for operators who aim to maximize equipment performance and improve overall operational efficiency.

Maintenance practices play a crucial role in ensuring the efficiency of gyratory crushers, which are integral to various mining and aggregate production operations. Regular inspections and maintenance can significantly enhance their performance and longevity, preventing unscheduled downtime that can be costly. According to industry reports, a well-maintained gyratory crusher can achieve an operational efficiency of up to 93%, compared to only 70% for those that are not properly maintained. This efficiency is critical in maximizing production and reducing operational costs.

One of the fundamental maintenance practices involves regularly checking and replacing wearing parts, such as liners and mantles. Studies have shown that the optimal life of these components can extend beyond 6,000 operating hours when properly monitored and replaced as needed. Additionally, lubrication systems must be inspected to ensure proper functioning, as inadequate lubrication can lead to increased friction and ultimately, machine failure. Implementing predictive maintenance strategies, such as vibration analysis and thermal imaging, further enhances the ability to foresee potential issues before they result in costly repairs, thus maintaining high levels of productivity and site profitability.

Gyratory crushers are crucial components in the mining and aggregate industries, providing efficient size reduction of materials. However, their complexity can lead to several operational issues that impact performance. One common issue is the wear and tear of crusher components, particularly the mantle and concave. According to a report by the Mine Safety and Health Administration, improper maintenance can increase the risk of unplanned downtime by as much as 30%, leading to significant financial losses. Regular inspections and timely replacement of worn parts can help alleviate these issues, ensuring optimal performance and longevity of the equipment.

Another prevalent problem is the potential for improper lubrication, which can result in overheating and increased wear on the bearings. A study published in the Journal of Mining Science highlighted that maintaining proper lubrication can reduce the incidence of catastrophic failures by up to 50%. Implementing a scheduled lubrication regimen, combined with monitoring systems that track temperatures and vibration levels, can be effective in avoiding lubrication-related failures. Additionally, addressing common operational challenges, such as material buildup and obstruction in the discharge area, can enhance the efficiency of gyratory crushers and minimize unnecessary downtime. By understanding and addressing these issues, operators can significantly improve the reliability and performance of their crushing operations.

| Part | Function | Common Issues | Solutions |

|---|---|---|---|

| Mantle | Crushes material against the concave | Excessive wear and cracking | Regular inspection and timely replacement |

| Concave | Provides a surface for the material to be crushed against | Deformation and wear | Regular monitoring and replacement when worn |

| Spider | Supports the mantle and absorbs vibrations | Cracking and loosening | Periodic checks and reinforcement if necessary |

| Gyratory Shaft | Transmits power for crushing action | Bending and wear | Ensure proper alignment and regular lubrication |

| Hydraulic System | Controls the movement of the mantle | Leaks and pressure loss | Regular maintenance and checking for leaks |