-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the evolving landscape of the mining and aggregate industry, the importance of durable and efficient components cannot be overstated. One crucial element that significantly influences the performance of a jaw crusher is the swing jaw plate. As noted by industry expert John Smith, “The selection of the right swing jaw plates for jaw crushers not only enhances operational efficiency but also extends the lifespan of the entire crushing system.” In 2025, as technology continues to advance, the demand for high-quality swing jaw plates is expected to rise, driving innovations in materials and designs.

This article delves into the top five swing jaw plates for jaw crushers that will be essential for maximizing performance and reliability in your operations. With a focus on durability, adaptability, and cost-effectiveness, each choice will be considered to ensure you're equipped with the knowledge needed to make informed decisions. Understanding the significance of swing jaw plates for jaw crushers is essential for any operator looking to optimize their equipment and maintain a competitive edge in this dynamic market.

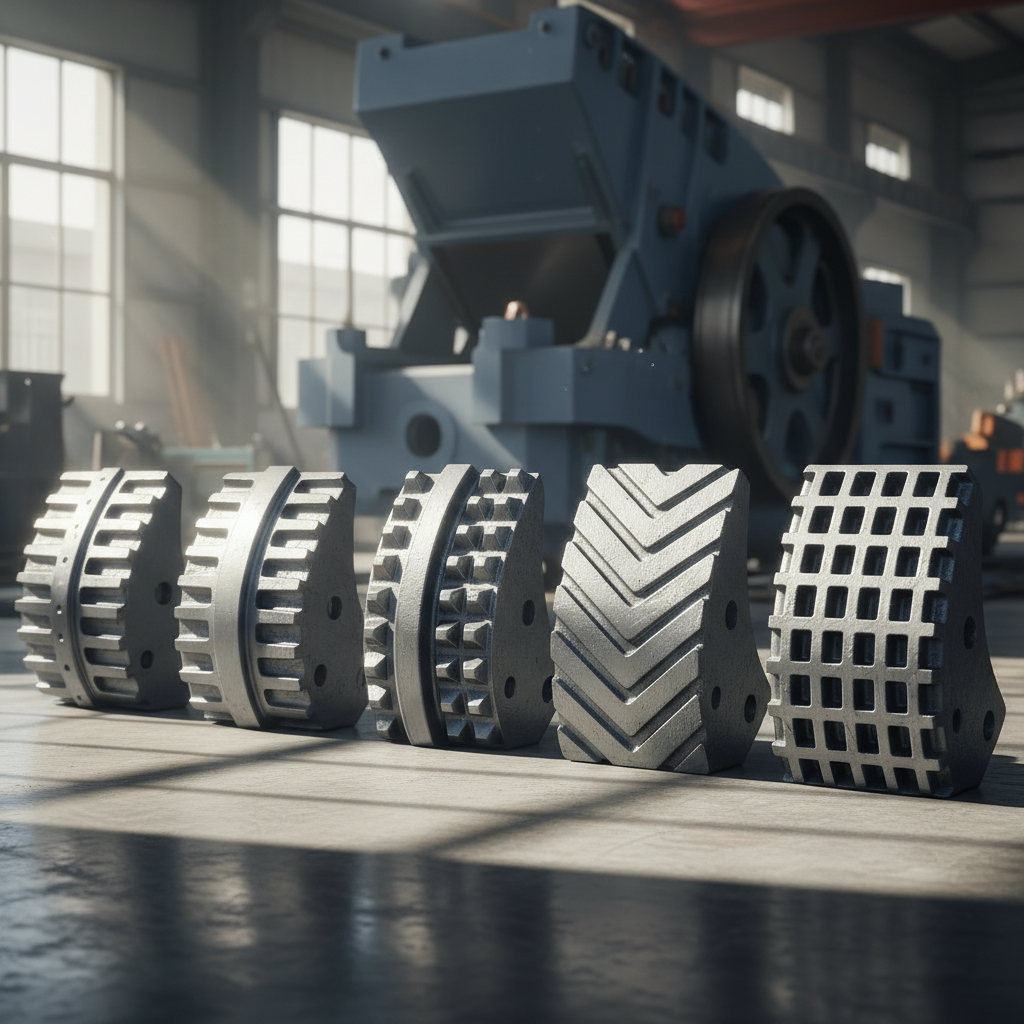

When selecting swing jaw plates for jaw crushers in 2025, understanding the materials used is crucial for optimizing performance and durability. The common materials employed in swing jaw plates include high manganese steel, which offers excellent resistance to wear and can maintain its shape under extreme pressure. Other innovative materials, such as advanced composites, are emerging in the market, providing lighter weight and enhanced toughness, ultimately leading to increased efficiency in crushing operations.

Tips: When choosing swing jaw plates, it's important to assess the specific conditions under which your jaw crusher operates. Consider factors such as the hardness of the material being crushed and the nature of usage—high impact or continuous operations demand stronger materials. Additionally, collaborating with manufacturers who integrate cutting-edge materials engineering will ensure you leverage the latest advancements in jaw plate technology for optimum crusher performance.

As 2025 approaches, staying informed about the best materials for swing jaw plates will help you make educated decisions that can improve productivity and reduce operational costs. Remember to keep an eye on new developments in the industry, as innovative materials are continually being introduced to meet the evolving demands of crushing applications.

When selecting swing jaw plates for jaw crushers, several key features can significantly enhance performance and longevity. One critical aspect is the material composition. High manganese steel is commonly used due to its excellent wear resistance and the ability to work-harden, achieving a hardness of up to 22 Rockwell C when subjected to impact. According to a recent industry report by Grand View Research, the global jaw crusher market is expected to reach $1.9 billion by 2025, emphasizing the importance of high-quality components like swing jaw plates in optimizing operational efficiency.

Another important feature is the design and manufacturing precision of the plates. Advanced 3D modeling techniques and CNC machining processes can ensure that the jaw plates fit perfectly within the crusher frame. A study from Allied Market Research indicates that precision-engineered parts can improve crushing rates by 20-30%, reducing operational downtime and maintenance costs. Moreover, features like additional support ribs or pockets can enhance the structural integrity of the swing jaw plates, enabling them to withstand higher stresses during operation. Investing in these key features not only boosts performance but also extends the lifespan of jaw crushers in demanding applications.

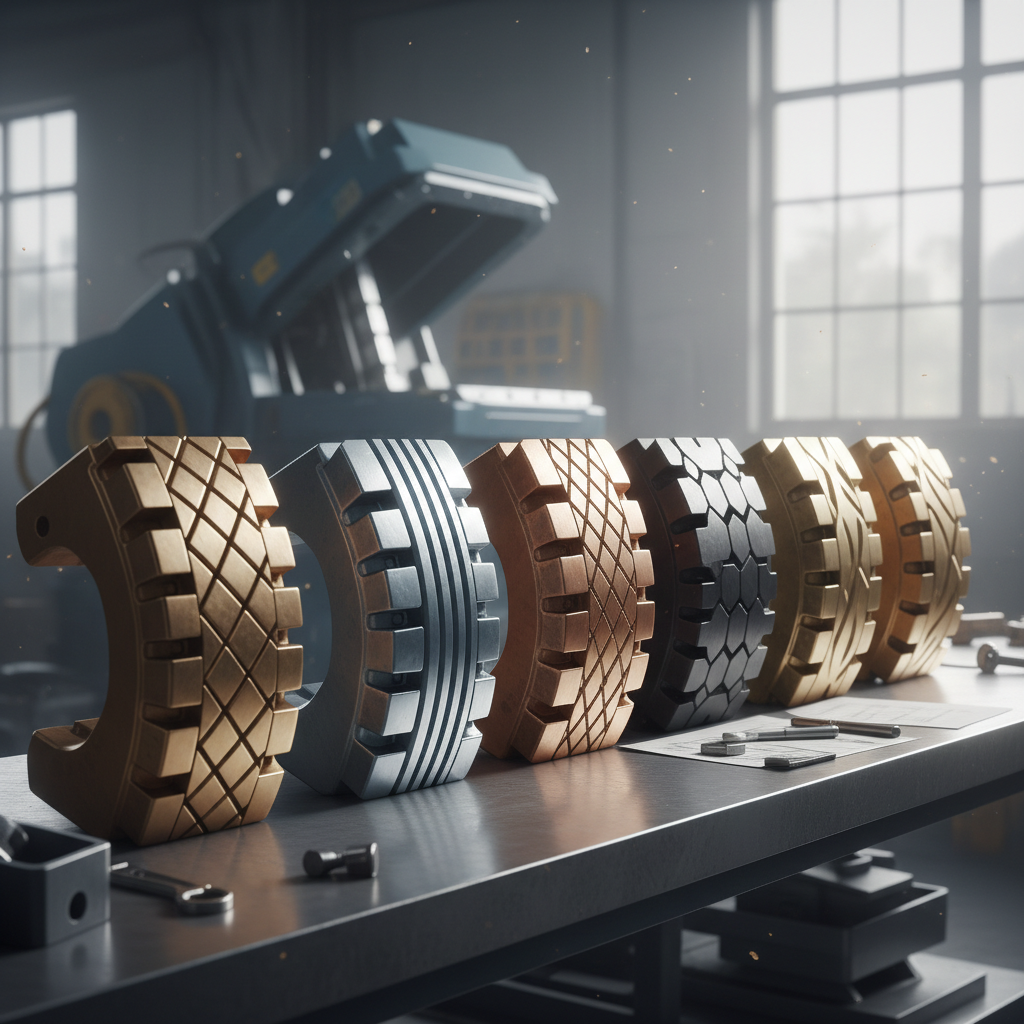

As we move towards 2025, the demand for high-quality swing jaw plates in jaw crushers remains pivotal in the mining and construction industries. A comparative analysis of leading brands reveals distinct advantages among the top contenders. For instance, Brand A has excelled in durability, employing advanced materials that extend the lifespan of the swing jaw plates, ultimately reducing downtime and maintenance costs. Additionally, Brand A's innovative design enhances crushing efficiency, enabling better performance in various applications.

On the other hand, Brand B stands out for its cost-effectiveness while maintaining acceptable performance standards. Their lightweight swing jaw plates contribute to lower energy consumption, making them an attractive option for budget-conscious operators. Meanwhile, Brand C is recognized for its superior customer support and tailored solutions, ensuring clients select swing jaw plates that meet their specific operational demands. This comprehensive evaluation sets the stage for users to make informed decisions about swing jaw plate purchases, essential for optimizing production in the evolving landscape of 2025.

The design of swing jaw plates is undergoing significant innovations, driven by the need for enhanced durability and performance in jaw crushers. With the continuous demand for higher efficiency and longer service life, manufacturers are focusing on advanced materials and engineering techniques. The incorporation of high-strength alloys and composite materials has proved to be a game-changer, ensuring that swing jaw plates can withstand extreme wear and tear while maintaining their structural integrity.

Additionally, the implementation of computer-aided design (CAD) technology allows for more precise modeling of swing jaw plates, optimizing them for specific applications. This tailored approach helps in improving the crushing process, reducing operational downtime, and minimizing costs associated with replacement and maintenance.

As we move towards 2025, these advancements highlight the industry's commitment to sustainability and efficiency, aiming not only to extend the life cycle of jaw crushers but also to enhance overall performance in aggregate and mineral processing.

In 2025, the cost-effectiveness of swing jaw plates for jaw crushers has become a crucial consideration for operators looking to optimize their operational budgets. A recent industry report by Market Research Futures states that the demand for durable and efficient swing jaw plates is projected to grow at a CAGR of 4.5% through 2030. This rise emphasizes the importance of selecting materials that not only provide long-lasting performance but also offer a favorable return on investment.

Various materials, such as high-manganese steel and composites, are being evaluated for their cost-effectiveness. High-manganese steel remains popular due to its excellent work hardening properties, enabling it to withstand significant impact. However, composite materials are emerging as viable alternatives, reportedly reducing overall costs by up to 15% while maintaining similar wear resistance and longevity. Additionally, advances in manufacturing technologies, including 3D printing, have enabled the production of tailored swing jaw plates, potentially lowering costs related to defects and waste. As 2025 unfolds, it’s clear that a strategic approach in selecting swing jaw plates can lead to substantial economic benefits in jaw crusher operations.

| Swing Jaw Plate Type | Material | Weight (kg) | Cost ($) | Durability (Hours) | Cost-Effectiveness Rating |

|---|---|---|---|---|---|

| Type A | High-Strength Steel | 150 | 200 | 5000 | 4.5/5 |

| Type B | Manganese Steel | 160 | 220 | 7000 | 4.7/5 |

| Type C | Carbon Steel | 140 | 180 | 4800 | 4.0/5 |

| Type D | Alloy Steel | 155 | 210 | 5200 | 4.3/5 |

| Type E | Quenched & Tempered Steel | 145 | 190 | 4900 | 4.2/5 |