-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

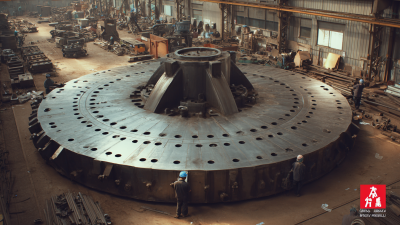

The Gyratory Crusher is a vital machine in the mining and construction industries. It excels at crushing large rocks into smaller, manageable sizes. Its design allows for continuous operation, making it efficient for high-volume production.

One key feature of the Gyratory Crusher is its ability to handle hard materials. It uses a unique crushing process to reduce rock size. However, the machine requires regular maintenance to perform optimally. This is an area where some operators struggle, often leading to unnecessary downtime.

Moreover, the Gyratory Crusher is known for its high crushing capacity. It can process several tons of material per hour. This efficient operation is essential for meeting production goals. Yet, some users remain unaware of its full capabilities. This oversight can undermine the benefits that the Gyratory Crusher offers. Understanding its features can enhance overall performance and productivity.

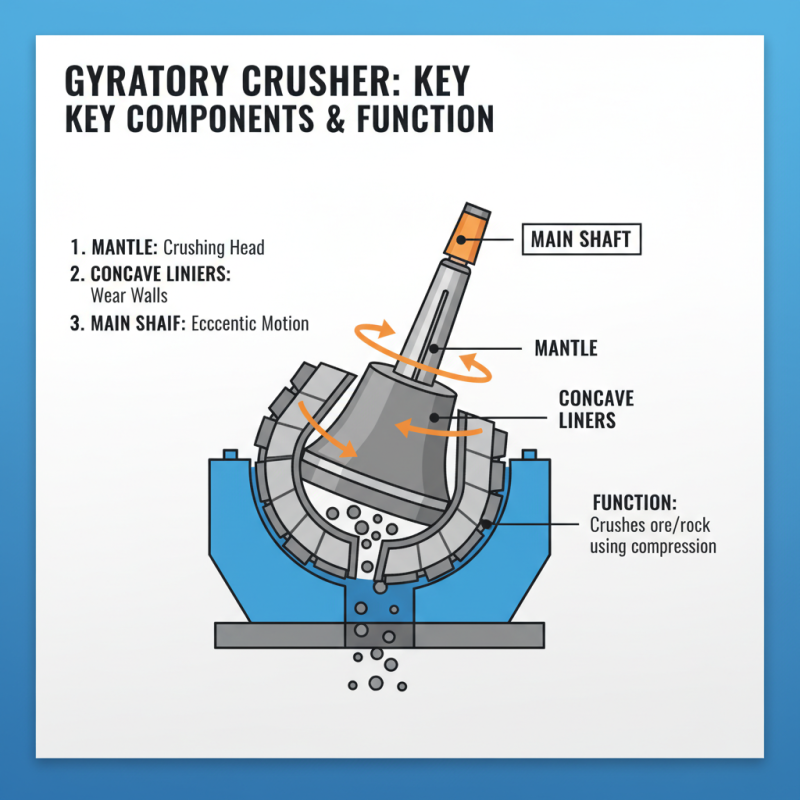

Gyratory crushers play a crucial role in mining and aggregate processing. Understanding their key components and functions helps in optimizing performance. The main parts include the mantle, concave liners, and the main shaft. Each part has a specific function that contributes to the crushing process.

The mantle is the moving part that exerts the force to crush material. This component wears down over time, which can affect efficiency. According to industry reports, replacing the mantle can improve production by up to 20%. The concave liners, or bowl, receive the material and direct it toward the mantle. They also wear out but are essential for consistent product size. Data shows that worn concaves can lead to a 15% decrease in output quality.

The main shaft supports the mantle and is critical for stability. It must withstand significant stress during operation. However, it can bend or fracture, leading to costly downtime. Regular inspections are necessary. Effective maintenance of these components can significantly extend their lifespan, ideally aiming for up to 5,000 hours of operational use. Overall, understanding these elements is key to maximizing efficiency in your operations.

Gyratory crushers play a crucial role in efficient crushing operations. Their design allows for a continuous flow of material, which enhances productivity. Understanding the crushing process is essential for optimizing performance. In these crushers, the material is crushed between a stationary cone and a rotating cone. This action generates both compressive and shear forces, yielding finer materials.

According to industry reports, gyratory crushers operate at a capacity rate of around 3,000 to 5,000 tons per hour. This output depends on several factors, including the size and composition of the input material. It is important to monitor these variables closely to avoid inefficiencies. Optimizing the settings can significantly impact the output quality.

Tip: Regularly inspect the liners and adjust the crushing gap. This can prolong the life of your equipment.

The efficiency of a gyratory crusher also relies on proper feeding. Material should be evenly distributed to prevent uneven wear. Too much variability can lead to faults in the equipment. This could hinder performance.

Tip: Implement a monitoring system to assess feed quality. It can help in maintaining consistent operation.

Gyratory crushers provide significant advantages for efficient crushing operations. They have a unique design that allows for continuous operation with minimal downtime. This feature is crucial in high-capacity applications. Gyratory crushers can handle large volumes of material, making them ideal for large-scale projects.

One of the key benefits is their ability to handle hard materials. They crush materials more effectively than other types of crushers. This resilience helps in maintaining high productivity levels. The shape of the crushing chamber enables better material flow. It prevents blockages and reduces the time spent on maintenance. However, understanding wear patterns is crucial. Operators may overlook how wear impacts efficiency.

Tips: Monitor wear and tear closely. Regularly inspect the crushing chamber. Adjust settings promptly to improve performance. Maintenance can sometimes feel like a hassle, but it's essential for optimal results. Effective crushing depends on understanding your equipment. Often, operators underestimate the importance of regular checks. Small changes can yield substantial improvements.

Regular maintenance is critical for the optimal performance of a gyratory crusher. This involves routine checks on components such as the mantle and concave. These parts wear over time and need proper inspection. Operators should keep an eye on wear patterns. Uneven wear can indicate that adjustments are necessary. A well-maintained crusher can increase efficiency significantly.

Proper lubrication is essential for reducing friction. Operators often overlook this step, leading to potential failures. Greasing should be done as per the manufacturer's guidelines. Additionally, the tightness of bolts and other fasteners should be regularly checked. Loose components can lead to vibration issues, which affect the overall performance of the machine.

It's important to track operational data regularly. Monitoring parameters like RPM and power consumption can help identify anomalies. Not all operators take the time for this analysis. A lack of attention could lead to costly repairs later. Being proactive can save time and money. Regular training on maintenance practices may help reduce human error.

The gyratory crusher plays a crucial role in the mining and aggregate industries. Recent innovations in its design have dramatically improved efficiency. These advancements focus on enhancing the machine's overall performance and lifespan. Modern gyratory crushers feature advanced automation systems. They offer real-time monitoring of wear rates and operational efficiency. This leads to reduced downtime and maintenance costs.

Operators are encouraged to consider various aspects before purchasing a gyratory crusher. Understand the specific materials you will crush. Not all crushers handle the same type of material efficiently. Analyze the required capacity and discharge size as well. These factors heavily influence the choice of the crusher. Testing different models at actual operation sites may yield valuable insights.

With the evolution in technology, manufacturers are designing crushers that are easier to operate and maintain. Innovations include improved hydraulic systems for adjusting the crushing gap. Furthermore, new materials are being utilized for key components. These materials can withstand greater wear and tear, extending equipment life. Even with these benefits, challenges still exist. Operators must be vigilant in monitoring and maintaining the equipment effectively. Regular training for staff is also vital. Always keep refining the operational practices for optimal results.

| Feature | Description | Benefits |

|---|---|---|

| High Capacity | Designed for high throughput and handling of large volumes of material. | Increased productivity and efficiency in crushing operations. |

| Durable Construction | Constructed with robust materials to withstand harsh working conditions. | Extended service life and reduced maintenance costs. |

| Advanced Automation | Incorporates smart technology for enhanced operation control. | Optimized performance and reduced operator workload. |

| Energy Efficiency | Utilizes designs that minimize energy consumption during operation. | Lower operational costs and reduced environmental impact. |

| Versatile Applications | Effective for a wide range of materials and mining applications. | Flexibility to fit various crushing needs and materials. |