-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Understanding Impact Crusher Wear Parts is essential for optimal performance. These components play a crucial role in the crusher's efficiency. They face heavy wear during operations, leading to significant maintenance costs.

In this overview, we’ll highlight the top ten wear parts. Each part is vital for maintaining the machine's productivity and lifespan. Knowing these components helps in making informed decisions. You'll find that regular inspections and timely replacements are important.

It’s surprising how many overlook the significance of Impact Crusher Wear Parts. Ignoring wear can lead to operational failures. However, dedicating attention to these elements ensures smoother operations. It ultimately saves time and money in the long run. Understanding these parts serves as a foundation for better maintenance practices.

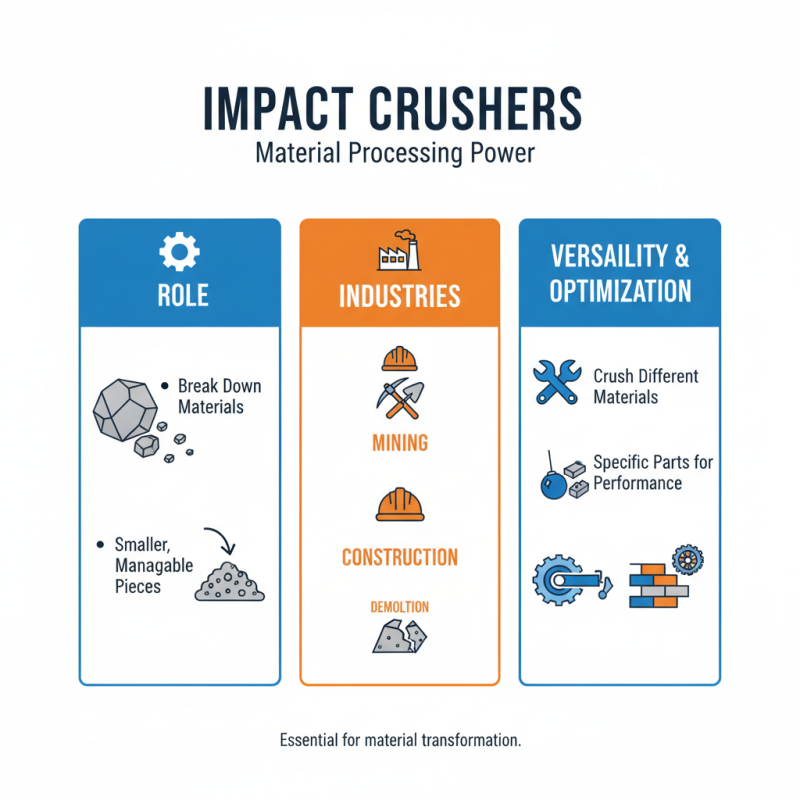

Impact crushers play a significant role in material processing. They are designed to break down various materials into smaller, manageable pieces. This process is essential in mining, construction, and demolition industries. The ability to crush different materials makes these machines highly versatile. Operators often find themselves needing specific parts to ensure optimal performance.

Understanding the components of impact crushers is crucial. Wear parts, for instance, are critical to the machine’s efficiency. Hammers, blow bars, and liners wear down with use. If not maintained or replaced, they can lead to poor crushing performance. Choosing the right parts can affect the overall process significantly. It's common for operators to overlook the importance of these components until failure occurs, revealing gaps in maintenance routines.

Regular inspection and proactive replacement of wear parts are necessary. This approach can prevent costly downtime. However, many still ignore warning signs, leading to bigger issues down the road. A lack of attention to detail in managing wear parts can hinder productivity. Balancing cost with quality remains a challenge, as some may opt for cheaper alternatives that fail sooner. Understanding the wear dynamics can enhance efficiency, ultimately benefiting material processing efforts.

Impact crushers play a crucial role in various industries, particularly in the processing of materials. Understanding the key components of impact crusher wear parts can significantly enhance operational efficiency. The blow bars are among the most critical wear parts. They directly strike the material, leading to wear and tear. This necessitates regular inspection to ensure optimal performance.

Another essential component is the liner plates. These plates protect the interior of the crusher. They wear down over time, impacting the crusher's efficiency. Monitoring the condition of liner plates can prevent unexpected breakdowns. Additionally, impact plates serve a vital purpose. They absorb shock and help redirect the material flow.

While maintaining these parts is important, doing so can be a challenge. Operators often overlook small signs of wear. This neglect can lead to more significant issues later on. Understanding the role of each component facilitates better maintenance practices. Proper care and timely replacements are keys to maximizing the lifespan of impact crusher wear parts.

Impact crushers are crucial in many industries, breaking down various materials into usable sizes. Understanding the essential wear parts is necessary for maintaining efficiency. These components endure significant stress and wear from constant impact and abrasion.

The blow bars of an impact crusher are a primary wear part. They face the brunt of material impact. Choosing the right material for blow bars affects durability and performance. Another vital component is the impact plates. They protect the internal parts from damage and contribute to crushing efficiency. Wear on these plates can lead to reduced output and quality.

Additionally, maintaining wear liners is critical. These liners protect the casing and help in controlling the flow of materials. A worn liner can result in improper functioning. Regular checks can prevent major breakdowns. Researching the right replacement parts can lead to better decision-making. These reflections can help improve longevity and productivity in operations.

Wear and tear in impact crusher parts can significantly affect performance. Recognizing the signs early can prevent costly downtime. Common indicators include unusual vibrations or noises. These abnormalities often suggest that parts are nearing the end of their lifespan. Also, check for inconsistencies in product output. An increase in fines or a decrease in the desired material size can signal wear on the impact plates or hammers.

Another critical sign is visible damage. Cracks or chips in crucial components can impact efficiency. It's essential to inspect these parts regularly. Monitoring for excessive wear can save money in the long run. Operators often ignore minor signs, leading to more significant issues. Regular maintenance should include thorough inspections of wear parts. Implementing a proactive approach is vital for maintaining optimal performance. If problems are overlooked, production could suffer significantly, highlighting the importance of diligence in monitoring wear.

Maintaining impact crusher wear parts is crucial for optimal performance. Regularly inspecting these parts helps identify wear and damage early. It’s essential to replace worn parts on time to prevent further complications. Small cracks or chips can lead to bigger issues. Monitor the impact plates, blow bars, and liners closely. Ignoring small signs can escalate repair costs.

When replacing wear parts, proper installation is key. Misalignment can cause premature wear or damage to adjacent components. Ensure all parts fit correctly. Use the manufacturer’s specifications for guidance. Don't rush the replacement process. Taking time here can enhance longevity.

It’s worth noting that even the best maintenance practices may not prevent all wear. Some parts might still wear out quicker than expected. This can be puzzling, especially when conditions seem ideal. Review your operational standards frequently to adapt to changing environments or materials. Understanding these variables can lead to better decision-making in maintenance and replacement.

| Part Name | Material | Typical Lifespan | Replacement Tips |

|---|---|---|---|

| Blow Bar | High Chromium Alloy | 500-700 hours | Inspect regularly for wear and replace when needed |

| Impact Plate | Abrasion Resistant Steel | 400-600 hours | Check alignment and replace if cracked |

| Crusher Liners | Manganese Steel | 700-900 hours | Monitor wear pattern and replace when significant wear is observed |

| Side Liners | High Carbon Steel | 500-700 hours | Ensure secure fit and replace if they become loose |

| Toggle Plate | Cast Iron | 1000-1200 hours | Change if there is any deformation or sign of fatigue |

| Hammer | High Manganese Steel | 300-500 hours | Inspect for cracks; replace if wear exceeds tolerance |

| Frame | Welded Steel Plate | Indefinite with maintenance | Regularly inspect for structural integrity |

| Feed Tube | Wear-Resistant Alloy | 400-600 hours | Replace if wear leads to misfeeding |

| Screws and Bolts | Stainless Steel | Indefinite with periodic checks | Tighten regularly; replace if they show significant wear |

| Bearing | High Strength Alloy | 800-1000 hours | Lubricate regularly and replace if noise increases |