-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of mining and construction, selecting the right Jaw Crusher Wear Parts is crucial. These components face harsh conditions and can significantly impact operational efficiency. According to a recent report by the Global Mining Association, poor wear part selection can lead to a 30% increase in maintenance costs. Ensuring optimal performance begins with understanding the specific requirements of your operations.

Expert in mining technology, Dr. Peter Collins, states, “Choosing the right wear parts is essential for maximizing productivity.” His insight highlights the necessity of meticulous attention when selecting these components. The variety in materials and designs can be overwhelming. A miscalculation here not only affects productivity but can also lead to safety hazards.

For instance, using subpar materials may seem cost-effective initially. However, the long-term repercussions can outweigh these savings. It's imperative to analyze wear patterns, past performance, and the specific characteristics of your operating environment. Remember, each wear part plays a unique role in the performance of your jaw crusher. Reflect on your choices to ensure they stand the test of time.

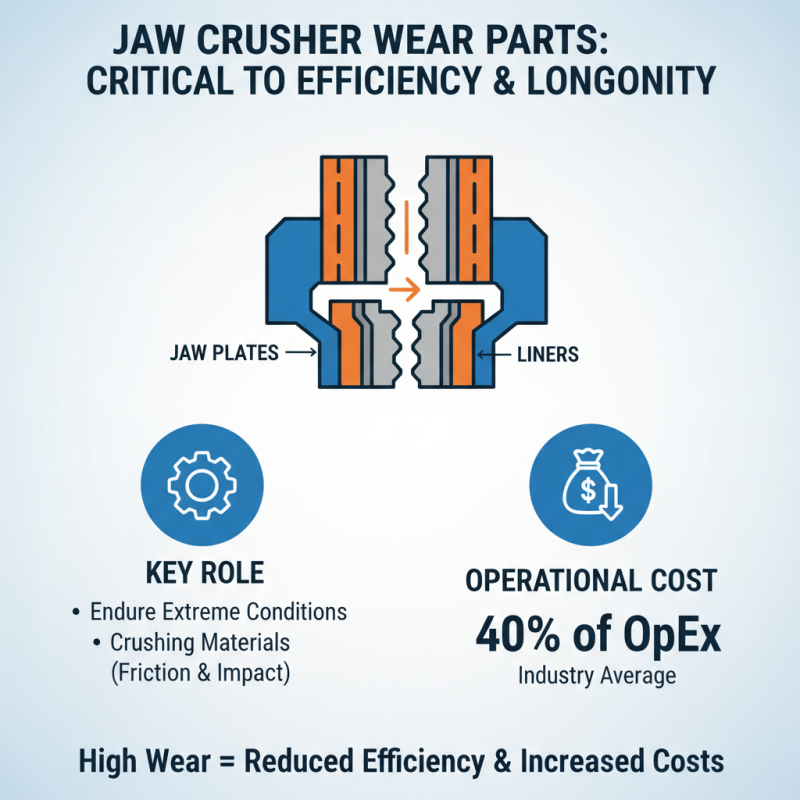

Wear parts in jaw crushers play a critical role in the machine's efficiency and longevity. These components, including jaws and liners, endure extreme conditions while crushing materials. They must withstand high levels of wear due to friction and impact. According to industry reports, wear parts account for roughly 40% of operational costs in crushing operations.

Selecting the right wear parts is essential. A good fit can increase productivity. Consider the material hardness and the type of material being processed. For example, if the material is more abrasive, opt for stronger materials. High manganese steel is popular for its work-hardening properties. The combinations of these properties can boost production by nearly 25%, according to recent studies.

Choosing wear parts based solely on price may lead to disappointment. Cheap options often wear out faster, leading to increased downtime. Assess the manufacturer's history and customer reviews. Look for indications of quality, like certifications. Avoid parts that lack clear specifications or performance data. A little research goes a long way in ensuring you make the right choice.

When selecting wear parts for jaw crushers, several factors come into play. The material quality of wear parts significantly affects performance. For instance, high manganese steel is renowned for its excellent wear resistance. According to industry reports, using premium materials can enhance the lifespan of these components by up to 30%.

Understanding the operating environment is crucial. If the crusher handles abrasive materials or operates in harsh conditions, selecting the right wear part composition becomes essential. Poor choices can lead to premature wear and costly downtime.

**Tip:** Always consider the percentage of recycled materials in the wear parts. Too much recycling can weaken the integrity of the parts.

Another aspect is the design of the wear part itself. Different jaw configurations may suit specific applications better. Ignoring these design nuances might result in inefficient crushing or increased operational costs.

**Tip:** Regularly review wear part performance. Keep records of parts’ lifespan and adjust future orders based on this real data.

Additionally, consult with industry experts. They can provide insights into the latest material advancements and effective wear part solutions tailored for your needs.

| Tip No. | Tip Description | Factors to Consider | Material Type | Cost Efficiency |

|---|---|---|---|---|

| 1 | Understand Material Properties | Impact, abrasion, hardness | Manganese steel | Balanced cost vs. durability |

| 2 | Check Compatibility | Model specifications | High chrome | Longer wear life |

| 3 | Evaluate Manufacturing Process | Casting quality | Alloy grades | Reduce wear replacement costs |

| 4 | Consider the Crusher's Working Conditions | Operating hours, capacity | Low alloy steels | Optimize material usage |

| 5 | Look for Manufacturer's Warranty | Durability guarantees | Wear-resistant materials | Protect investment |

| 6 | Monitor Replacement Frequency | Cost of downtime | Bimetallic materials | Minimize operational costs |

| 7 | Assess Impact Resistance | Breakage patterns | Work hardening steel | Enhanced longevity |

| 8 | Consult Experts | Professional insights | Custom alloys | Improved performance |

| 9 | Review Customer Feedback | User satisfaction | Quality alloys | Higher trust in products |

| 10 | Evaluate After-Sales Support | Service availability | Upgrades | Dependable service |

When selecting wear parts for jaw crushers, materials play a crucial role. Common choices include manganese steel, high chromium iron, and carbon steel. Manganese steel is renowned for its high impact strength and durability. It can withstand heavy loads and resist wear effectively. High manganese content allows it to be work-hardened in service, making it ideal for crushing hard materials.

High chromium iron is another popular option. This material excels in abrasive environments. It offers superior resistance to wear and prolongs the life of wear parts. However, it is more brittle than manganese steel. In certain applications, this could lead to premature failure. Understanding the trade-offs is essential to avoid costly downtime.

Carbon steel is less commonly used for wear parts. Though less expensive, it does not deliver the same wear resistance. It might be suitable for low-impact applications, but its longevity in more demanding conditions is questionable. Many operators overlook this aspect, often regretting their choice when replacements become necessary sooner than expected. Selecting the right material is essential to maximizing both performance and cost-effectiveness in your operations.

When selecting wear parts for jaw crushers, evaluating supplier credentials is essential. High-quality parts are critical for efficiency and longevity. Researching the supplier's experience in the industry can provide insights. Look for years of operation and customer testimonials. A strong track record often indicates reliability.

Certificates and standards play a key role. Suppliers should meet industry norms. This ensures their products have undergone rigorous testing. Moreover, inquire about the materials used. Quality steel and alloys can significantly impact performance. Don't shy away from asking about sourcing practices. Sustainable and responsible sourcing can indicate a trustworthy supplier.

It's also wise to assess after-sales support. What kind of warranty do they offer? Is there a process for handling defects? Understanding this can prevent future headaches. Sometimes suppliers may appear solid but lack adequate follow-up. Investigating their customer service reputation may expose areas for improvement. Consider all these factors carefully before making a decision. Your choice could have significant consequences on your operation.

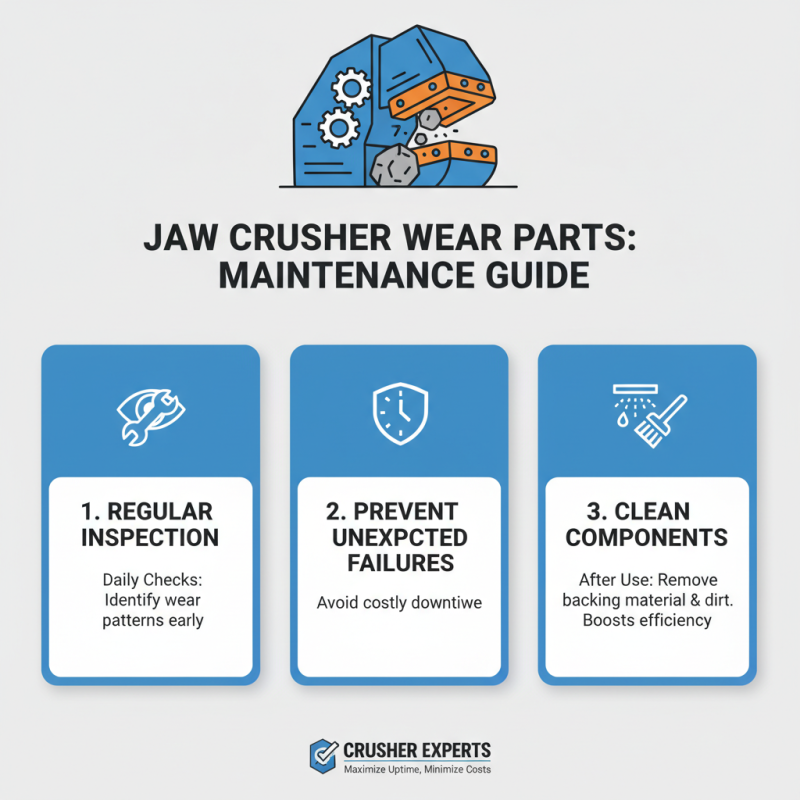

When maintaining jaw crusher wear parts, regular inspection is key. Daily checks help identify wear patterns early. This can prevent unexpected failures and costly downtime. Always clean the components after use. Backing material and dirt can increase wear. Ensuring that parts are free from debris aids efficiency.

Using the correct lubricants is essential. Regular lubrication minimizes friction and heat. Remember, excess grease can attract dirt. Balance is crucial here. Monitor the temperature of wear parts during operation. Elevated temperatures may indicate potential issues.

Besides maintenance, selecting the right materials is vital. Consider the crushing material and environment. Different situations require different wear parts. Sometimes, it’s worth investing in higher-quality options. Reflect on past experiences; have the chosen parts performed well? Learning from previous decisions can guide future choices for better outcomes.