-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the highly competitive aggregate and mining industries, the efficiency of jaw crushers is paramount for maximizing productivity and maintaining profitability. According to a report by the National Stone, Sand & Gravel Association, the demand for high-quality jaw crusher parts has surged, with a projected growth rate of 4.5% annually through 2025. This growth underscores the necessity for operators to invest in durable and reliable Jaw Crusher Parts, which contribute significantly to operational uptime and reduce maintenance costs. Quality components not only enhance the performance of the machinery but also ensure a longer lifespan, minimizing the frequency of part replacements. By understanding the critical role these parts play, companies can better navigate the challenges of crushing operations while optimizing their overall efficiency and output.

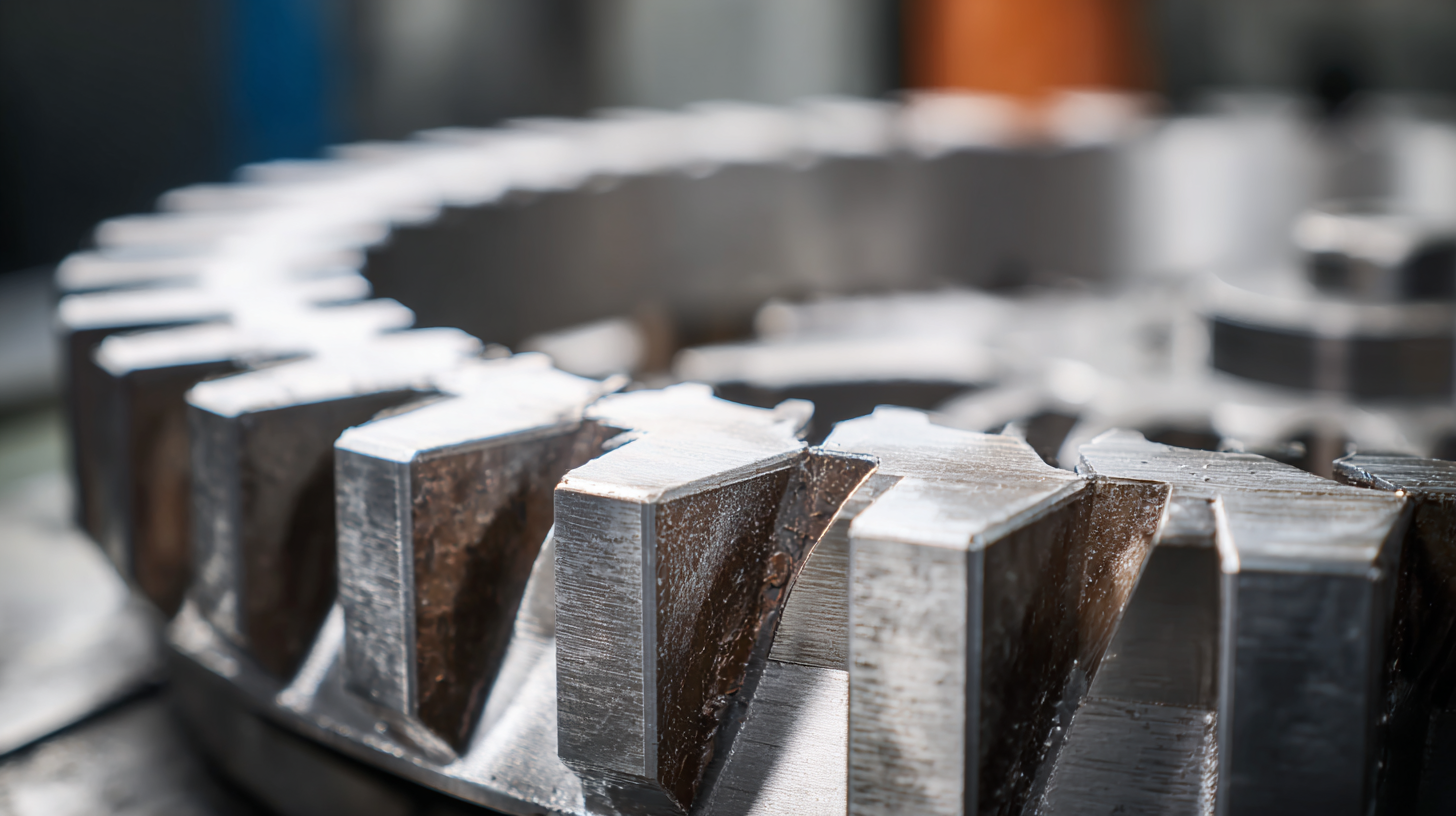

High-quality jaw crusher parts are essential for optimizing operational efficiency in crushing processes. These components, including jaw plates, bearings, and shafts, contribute significantly to the overall performance of the crusher. When manufactured to precise specifications with durable materials, they enhance the machine's ability to handle various materials effectively, thus reducing downtime and maintenance costs. High-quality parts minimize wear and tear, ensuring that the crusher maintains its shape and functionality over an extended period.

Additionally, investing in premium jaw crusher parts directly impacts productivity. A well-functioning jaw crusher can process a greater volume of materials with minimal energy expenditure, streamlining operations and maximizing output. Furthermore, precision-engineered parts ensure proper fit and alignment, reducing vibrations and improving the overall stability of the machine. This optimization not only leads to better resource utilization but also supports the sustainability of the operation by lowering energy consumption and reducing the frequency of maintenance intervals.

In the competitive landscape of jaw crusher performance, understanding and utilizing key performance indicators (KPIs) is vital for maximizing operational efficiency. Metrics such as throughput, downtime, and maintenance costs provide valuable insights into the machine's performance and help in making informed decisions. By focusing on these KPIs, operators can identify areas for improvement, ensuring that every component, including high-quality jaw crusher parts, is functioning optimally.

**Tips:** Regularly monitor and analyze the throughput ratio to ensure the crusher consistently meets production goals. Additionally, track downtime metrics closely; a reduction in unplanned maintenance can significantly enhance overall productivity. Understand the importance of the maintenance cost KPI, as investing in quality parts can yield long-term savings by extending equipment life and performance.

Another crucial aspect of utilizing KPIs is establishing a baseline for your operations. This allows for effective benchmarking and the ability to measure progress over time. By keeping these vital metrics in check, you can ensure that your jaw crushers perform at their peak, ultimately driving your business towards greater success in a demanding market.

When it comes to maximizing the performance of jaw crushers, selecting the right materials for parts is crucial for enhancing durability. According to the International Journal of Materials Research, components made from high-quality materials like manganese steel, which can withstand considerable wear and impact, significantly increase the lifespan of jaw crusher parts. Manganese grades such as 14%, 18%, and even 22% have shown superior resistance to abrasion and deformation under stress, making them ideal for high-intensity applications.

Additionally, incorporating alloys like chromium and nickel in the manufacturing process can further enhance strength and toughness. A report published by the Journal of Crushing Technology indicates that jaw crusher parts made from these materials can experience up to 30% longer life compared to standard materials, resulting in reduced downtime and lower operational costs. By leveraging advanced material science, manufacturers can produce jaw crusher parts that not only withstand extreme conditions but also deliver peak performance, driving efficiency and productivity in quarrying and mining operations.

To maximize the lifespan of jaw crusher components, implementing best maintenance practices is essential. Research indicates that regular maintenance can extend equipment life by as much as 30%. Ensuring that the jaw plates are properly aligned and consistently inspected for wear can significantly improve performance. A study from the Mining and Metallurgy Institute revealed that regular inspection can reduce the frequency of costly replacements, allowing operators to achieve optimal efficiency while minimizing downtime.

Moreover, lubrication plays a vital role in maintaining jaw crusher functionality. According to a report by the Association of Equipment Manufacturers, improper lubrication can lead to increased operational temperature, resulting in premature wear of components. It's recommended to adhere to manufacturers’ guidelines regarding lubricant types and intervals. Additionally, operators should consider implementing real-time monitoring systems that can track the condition of critical components, thus facilitating proactive maintenance strategies and reducing the likelihood of unexpected failures. By adopting these practices, businesses can enhance the performance of their jaw crushers and ensure sustainable operations.

Moreover, lubrication plays a vital role in maintaining jaw crusher functionality. According to a report by the Association of Equipment Manufacturers, improper lubrication can lead to increased operational temperature, resulting in premature wear of components. It's recommended to adhere to manufacturers’ guidelines regarding lubricant types and intervals. Additionally, operators should consider implementing real-time monitoring systems that can track the condition of critical components, thus facilitating proactive maintenance strategies and reducing the likelihood of unexpected failures. By adopting these practices, businesses can enhance the performance of their jaw crushers and ensure sustainable operations.

Investing in quality jaw crusher parts can significantly affect the long-term performance and operational costs of processing equipment. While the initial expense of high-quality components may seem daunting, a thorough cost-benefit analysis reveals that these investments can yield substantial savings over time. Premium parts are designed to withstand rigorous conditions, offering improved durability and reliability compared to their lower-cost counterparts. This reduced wear and tear can minimize frequent replacements, ultimately lowering maintenance costs and reducing downtime.

Moreover, the efficiency gained from using superior parts leads to enhanced productivity. High-quality components are optimized for performance, ensuring that the crusher operates at peak levels. This efficiency boost translates directly into better material processing and higher output rates, further justifying the initial investment. By choosing quality over quantity, companies not only improve their operational metrics but also pave the way for long-term financial sustainability, proving that investing in top-tier jaw crusher parts is not simply a cost but a strategic decision for success.

| Parts Quality | Initial Cost | Lifespan (months) | Replacement Frequency (per year) | Total Cost per Year | Overall Efficiency |

|---|---|---|---|---|---|

| High Quality | $2,500 | 24 | 1 | $2,500 | 95% |

| Medium Quality | $1,500 | 12 | 2 | $3,000 | 85% |

| Low Quality | $700 | 6 | 4 | $2,800 | 70% |