-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

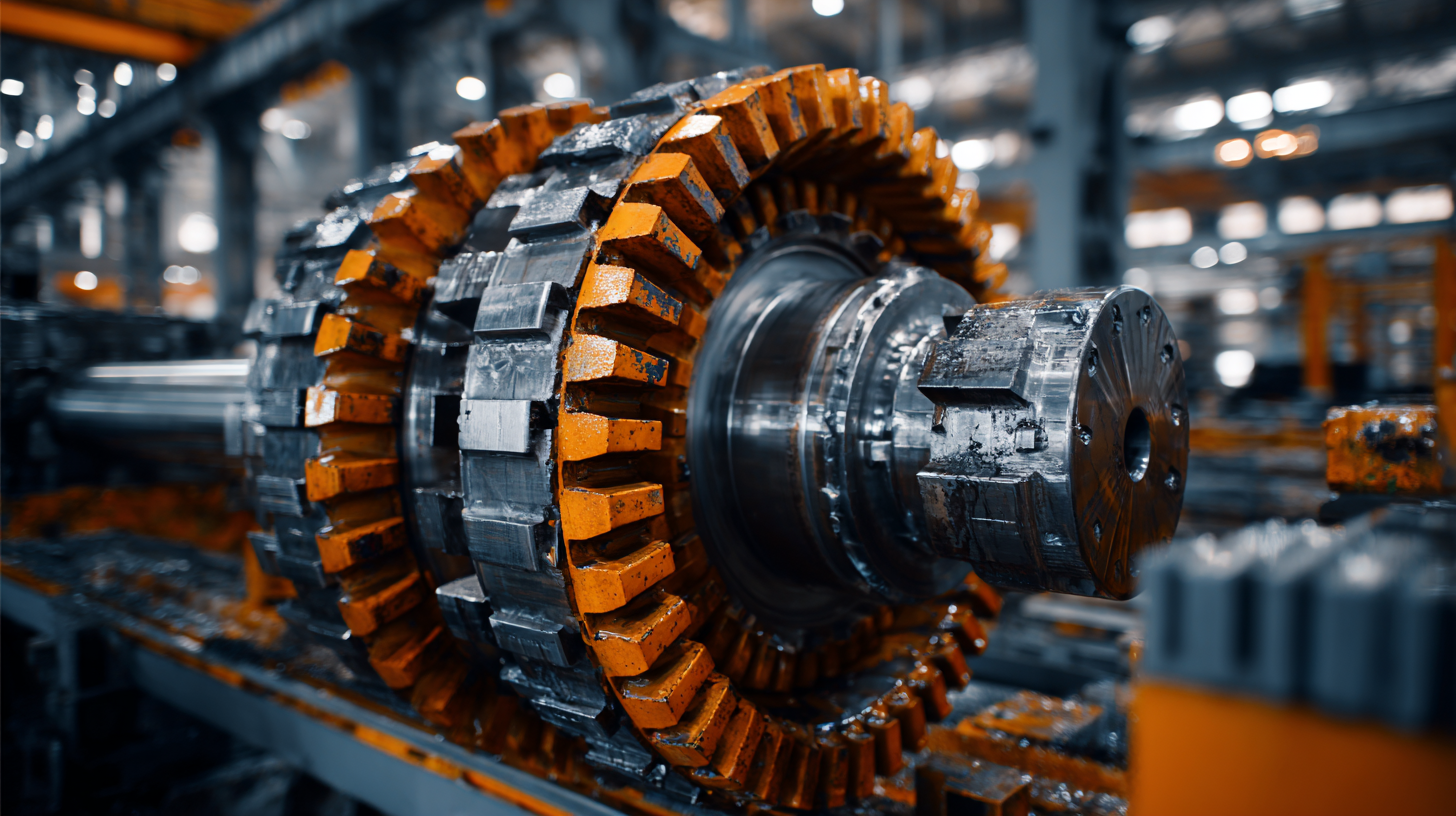

In the mining industry, the efficient operation of crushing equipment is paramount to achieving optimal productivity and profitability. Jaw crushers, known for their reliability and robustness, are indispensable in the initial stages of material processing. However, the effectiveness of these machines heavily relies on the performance and longevity of their components, particularly the Jaw Crusher Wear Parts.

According to a report by Freedonia Group, the global demand for wear parts in the mining sector is projected to exceed $4 billion by 2024, highlighting the critical nature of maintaining these parts to avoid costly downtimes and inefficient operations.

By implementing best practices for the maintenance and selection of high-quality Jaw Crusher Wear Parts, mining operations can significantly increase their equipment longevity and overall efficiency. This guide aims to provide actionable strategies for optimizing the lifespan and functionality of these essential components.

Daily maintenance of jaw crusher wear parts is crucial for maximizing efficiency and prolonging the lifespan of these components in mining operations. One of the best practices is to conduct regular inspections to identify wear patterns and potential issues before they escalate. By closely monitoring the condition of jaw plates, cheek plates, and other critical wear components, operators can schedule timely replacements and avoid unexpected breakdowns that might result in costly downtime.

Another essential maintenance practice involves proper lubrication. Ensuring that the wear parts are adequately greased reduces friction and prevents premature wear. Operators should follow manufacturer guidelines to use the correct type and amount of lubricant. Additionally, it is important to clean the grease fittings regularly to avoid contamination that could affect the performance of the wear parts.

Implementing these daily maintenance tasks not only enhances the operational efficiency of the jaw crusher but also ensures that wear parts function optimally for a more extended period, thus improving overall productivity in mining operations.

The material selection for wear parts in jaw crushers plays a crucial role in maximizing both efficiency and longevity during mining operations. The performance of wear parts directly influences the overall functionality of the crusher, and thus, choosing the right materials is essential. High-quality materials with appropriate hardness, toughness, and resistance to wear can significantly reduce the frequency of replacements and downtime. For instance, using manganese steel, known for its excellent impact strength and ductility, can result in longer-lasting wear parts that are better suited for handling variabilities in ore hardness.

Moreover, understanding the operating conditions and the type of material being processed is vital when selecting wear parts. Different applications may require specific material compositions to withstand particular wear mechanisms, such as abrasion or impact. Engineers and operational managers should analyze the mining environment and tailor their wear parts accordingly. This strategic approach not only improves operational efficiency but also enhances the cost-effectiveness of maintenance and replacements, ensuring that mining operations run smoothly and profitably over time.

| Material Type | Hardness (HRC) | Impact Strength (J/m²) | Wear Rate (g/ton) | Cost ($/kg) |

|---|---|---|---|---|

| High Carbon Steel | 58-62 | 30 | 0.4 | 1.20 |

| Manganese Steel | 12-14% | 60 | 0.5 | 1.50 |

| Chrome Alloy Steel | 58-64 | 50 | 0.3 | 1.80 |

| Ceramic Composite | 70-75 | 80 | 0.1 | 3.00 |

Monitoring wear patterns in jaw crusher wear parts is crucial to optimizing replacement schedules and enhancing overall mining operations. Utilizing IoT sensors enables real-time data collection, granting operators the ability to track wear rates and predict when components will require replacement. Predictive maintenance can significantly reduce downtime and costs associated with unexpected machinery failures. For instance, the Australian heavy machinery components market is projected to reach USD 5.8 billion by 2033, driven primarily by advancements in technology and the ongoing mining boom. This growth highlights the increasing importance of efficient equipment management.

As the industry embraces condition-based maintenance, the integration of artificial intelligence and machine learning is becoming more prevalent. These technologies aid in harnessing vast amounts of data generated from mining equipment to derive actionable insights. By monitoring wear patterns through advanced analytics, companies can schedule replacements precisely when necessary, thus maximizing the life cycle of wear parts. Research indicates that employing such predictive strategies can enhance efficiency by up to 20%, ensuring that mining operations run smoothly and effectively while minimizing costs associated with premature wear and unexpected failures.

Effective lubrication techniques are vital for enhancing the longevity and efficiency of jaw crusher wear parts in mining operations. Proper lubrication reduces friction and wear between moving components, which is crucial in high-stress environments like mining. By ensuring that the correct type and amount of lubricant are applied, operators can significantly decrease the incidence of premature wear and tear. This not only extends the life of the wear parts but also minimizes downtime caused by maintenance and replacements, ultimately leading to increased productivity.

Moreover, regular lubrication schedules should be integrated into the maintenance routines of mining operations. Utilizing automated lubrication systems can ensure that wear parts receive consistent and adequate lubrication without the interruption of manual application. It’s also beneficial to use quality lubricants that are specifically designed for high-load applications, as they can withstand the extreme pressures found within jaw crushers. Educating the maintenance staff on the significance of lubrication and providing them with the right tools and information can further enhance the effectiveness of these techniques, ensuring that jaw crushers operate at peak efficiency for an extended period.

This bar chart compares the optimal conditions versus current operations for maximizing the efficiency and longevity of jaw crusher wear parts in mining operations. The metrics analyzed include lubrication intervals, operating hours, maintenance frequency, and temperature control, highlighting areas for improvement in current practice.

In mining operations, the efficiency and longevity of jaw crusher wear parts significantly depend on effective wear parts management strategies. One of the key components to achieving this is through comprehensive training and education of the staff involved in the operation and maintenance of these machines. By implementing a structured training program, employees can gain a deeper understanding of the wear parts' roles, their behaviors under various conditions, and the necessary steps to prolong their lifespan.

Moreover, a focus on total quality management (TQM) principles can further enhance these training efforts. TQM emphasizes the importance of continuous improvement and error reduction at every stage of the manufacturing process. By intertwining TQM with wear parts management strategies, operations can minimize supply chain issues and optimize resource utilization. Enhanced training not only equips employees with the skills needed for effective wear parts management but also fosters a culture of quality and accountability within the workforce. This approach ultimately leads to reduced machine downtime, increased productivity, and improved overall operational efficiency in the mining sector.