-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

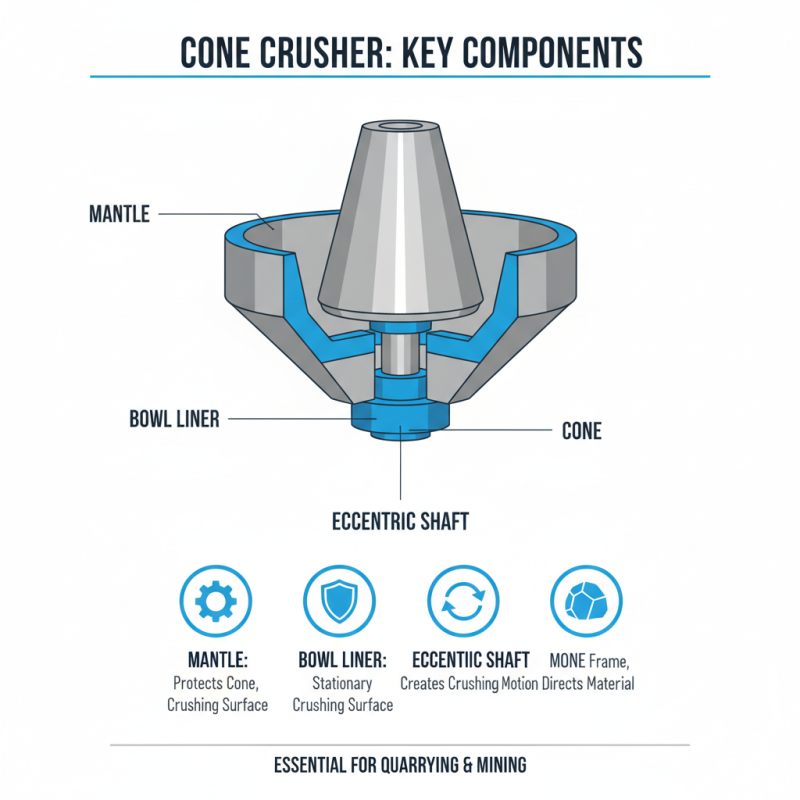

Cone crushers are essential in the mining and construction industries. They are used to break down materials into smaller pieces. Understanding Cone Crusher Components is crucial for their effective operation.

Key elements include the cone, mantle, and bowl liner. The cone is the main structure that produces compression. The mantle rotates around the cone, crushing materials that enter. The bowl liner forms the outer surface, guiding material flow. Each component plays a significant role.

The efficiency of a cone crusher depends on these parts working together. If one component wears down or fails, the machine's performance suffers. Regular maintenance of Cone Crusher Components is necessary. However, sometimes, this maintenance can be overlooked. Reflecting on these aspects helps improve operations and extends machinery life.

A cone crusher plays a vital role in aggregate processing. This machine crushes material by using a rotating cone within a fixed outer shell. The main function is to break down larger rocks into smaller, usable sizes. This is essential for producing quality aggregates used in construction and other applications.

One key function is the ability to adjust the size of the output. By changing the gap between the cone and the shell, operators can control the size of the crushed material. This flexibility allows for different types of aggregates to be produced from various materials. However, achieving the perfect balance can be tricky. If the gap is too wide, the product may be too coarse. If it’s too narrow, you may end up with an excess of fines.

Efficiency is another crucial aspect of a cone crusher. Proper maintenance is necessary to ensure optimal performance. Clogged feed openings can lead to reduced efficiency. Regular checks and adjustments help prevent this issue. Additionally, operators must be careful with feed material. Using wet or sticky materials can lead to problems with crushing consistency.

| Component | Function | Material | Maintenance Tips |

|---|---|---|---|

| Cone Head | Crushes material through compression | High manganese steel | Regularly check for wear and replace as necessary |

| Mantle | Forms the main crushing surface | Alloy steel | Inspect for cracks and wear |

| Bowl Liner | Supports the cone head and controls product size | High chrome iron | Replace when worn to maintain efficiency |

| Hydraulic System | Adjusts the closed side setting and provides overload protection | Hydraulic fluid | Check fluid levels and for leaks regularly |

| Feed Hopper | Facilitates the introduction of material into the crusher | Steel or coated material | Keep clean and check for blockages |

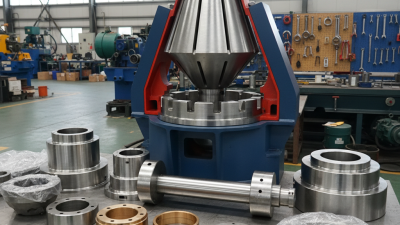

A cone crusher is essential in various quarrying and mining operations. Its design includes several key components that contribute to its effectiveness. The main parts include the cone, mantle, bowl liner, and eccentric shaft. Each plays a vital role in the crushing process.

The cone is a crucial part that helps in crushing the material. The mantle and bowl liner work together to create a chamber. This chamber compresses the material, ensuring effective size reduction. According to industry reports, a well-maintained cone crusher can achieve a reduction ratio of up to 6:1. However, wear on the mantle and bowl can impact performance significantly.

Another critical aspect is the eccentric shaft. It drives the mantle's movement, affecting the crushing capacity. If the shaft is misaligned or damaged, it can lead to reduced efficiency. Regular inspection of these components is necessary. Ignoring wear and tear can lead to costly repairs. Analyzing operational data shows that typical downtime due to maintenance issues can be around 20%. Making timely adjustments can drastically improve productivity.

Understanding the crushing mechanism of cone crushers is vital for optimizing performance. Cone crushers are commonly used for secondary and tertiary crushing. They are known for their efficiency and ability to produce high-quality aggregates. The crushing action takes place between a fixed cone and a movable cone, often referred to as the mantle. As the mantle oscillates, it creates a narrowing space where rocks are compressed.

According to a recent industry report, cone crushers can achieve a throughput of 600 tons per hour. The design allows them to handle various materials, from hard rocks to softer ores. However, the complexity of the crushing mechanism can lead to operational challenges. Poorly calibrated settings may result in excessive wear or reduced productivity. One study indicated that incorrect adjustment could lead to a 20% decrease in output.

The hydraulic system plays a crucial role in maintaining the cone position. It helps manage the crushing chamber's pressure. However, this system can sometimes cause issues if not monitored regularly. Over-reliance on automation may obscure underlying problems. Regular maintenance checks are essential to ensure optimal functioning. An unheeded problem might lead to unexpected breakdowns, disrupting production schedules.

Material selection is crucial for the performance of cone crusher components. High manganese steel is commonly used for wear parts. This material can withstand significant impact forces. However, it has its limitations. It may not perform well under extreme temperatures. An analysis by industry experts indicated that using alternatives like alloy steel could improve durability.

Choosing the right material impacts both efficiency and maintenance costs. Poor material selection can lead to frequent replacements. This not only increases downtime but also affects production rates. Studies show that optimized material choices can enhance component life by up to 30%. This can translate into substantial savings for operators in the long run.

Additionally, the hardness and toughness of materials vary significantly. Sometimes, a balance between these properties is overlooked. For instance, a component that is too hard may become brittle. Insufficient toughness leads to cracks and failures. Proper testing and analysis can guide the right choices. The industry's best practices suggest regular evaluations of materials under operational conditions. This can lead to ongoing improvements and refinements in cone crusher designs.

This bar chart displays the durability of different materials used in cone crusher components. Manganese Steel shows the highest durability, followed by Alloy Steel, High Chromium Iron, and Ceramic Materials, indicating the significance of material selection for optimal performance.

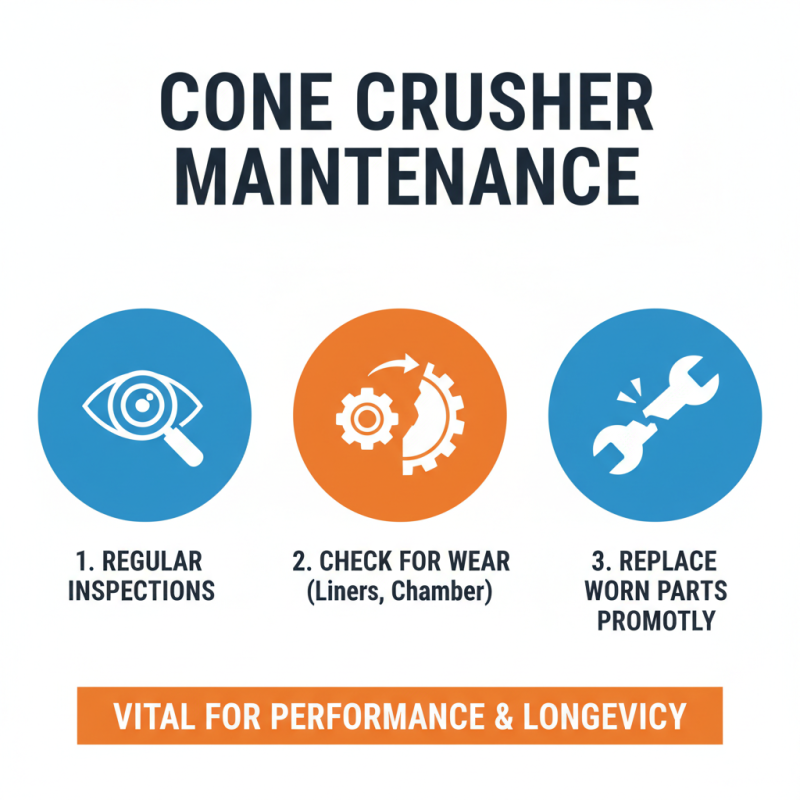

Proper maintenance of a cone crusher is vital for its performance and longevity. Regular inspections are necessary. Check for wear on various components, such as liners and the crushing chamber. If parts show significant wear, replace them promptly. Waiting too long can lead to further damage and higher costs.

Lubrication is another critical aspect. Use the correct type of oil and monitor levels frequently. Over time, oil can degrade, losing its effectiveness. Don’t overlook this step. Inspect seals and gaskets to prevent leaks, which can cause malfunctions.

Dust and debris can accumulate within the machine. Regular cleaning helps maintain optimal operations. However, this task can be time-consuming. It's tempting to skip it for convenience. Yet, failure to keep a clean environment can lead to reduced efficiency. Addressing these issues early on is crucial to avoid bigger problems later.