-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

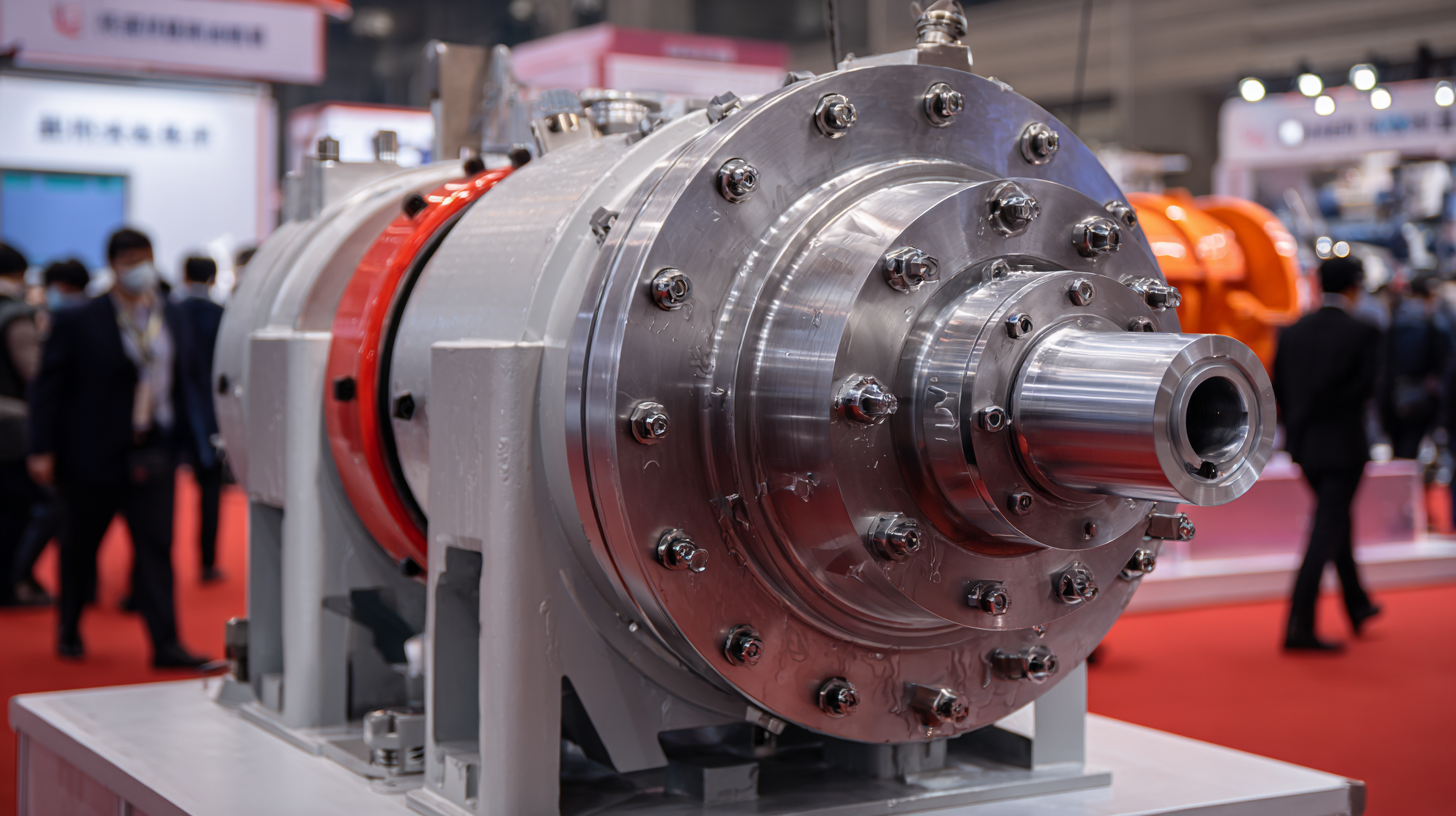

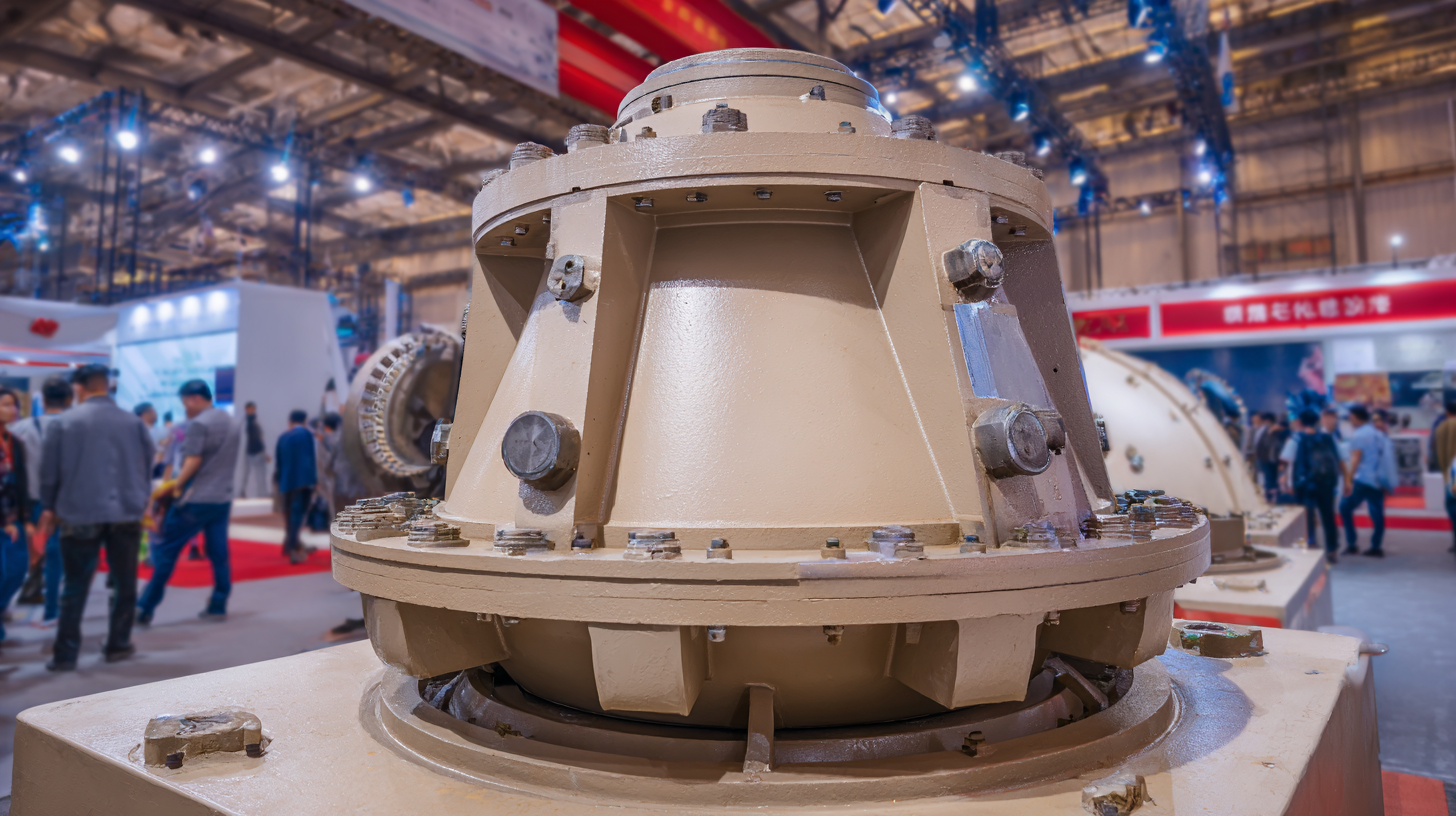

In the rapidly evolving landscape of the mining industry, the innovative trends in Cone Crusher Bowl technology are poised to make a significant impact. As we gear up for the 2025 China Import and Export Fair, the focus on advanced machinery and equipment will highlight the crucial role of Cone Crusher Bowls in enhancing operational efficiency and performance. These cutting-edge designs not only contribute to increased productivity but also emphasize sustainability by optimizing resource utilization. With a growing demand for high-performance mining solutions, the integration of innovative features in Cone Crusher Bowls will address the challenges faced by industry players, setting a new standard for excellence in mining operations. This exhibition will serve as a platform to showcase the transformative potential of these technologies, thereby shaping the future of the mining industry.

In the rapidly evolving landscape of the mining industry, the innovative trends in Cone Crusher Bowl technology are poised to make a significant impact. As we gear up for the 2025 China Import and Export Fair, the focus on advanced machinery and equipment will highlight the crucial role of Cone Crusher Bowls in enhancing operational efficiency and performance. These cutting-edge designs not only contribute to increased productivity but also emphasize sustainability by optimizing resource utilization. With a growing demand for high-performance mining solutions, the integration of innovative features in Cone Crusher Bowls will address the challenges faced by industry players, setting a new standard for excellence in mining operations. This exhibition will serve as a platform to showcase the transformative potential of these technologies, thereby shaping the future of the mining industry.

The mining industry is undergoing a significant transformation with innovative enhancements in cone crusher bowl technology. The upcoming 2025 China Import and Export Fair highlights the critical advancements aimed at improving operational efficiency and resource management. In recent reports, the trend towards designing crushers that offer greater structural integrity and reduced downtime is evident. For instance, the latest advancements have resulted in machinery that boasts up to 30% higher throughput compared to previous models. This crucial improvement not only optimizes resource extraction but also minimizes operational costs, making it a pivotal shift for mining operations.

The mining industry is undergoing a significant transformation with innovative enhancements in cone crusher bowl technology. The upcoming 2025 China Import and Export Fair highlights the critical advancements aimed at improving operational efficiency and resource management. In recent reports, the trend towards designing crushers that offer greater structural integrity and reduced downtime is evident. For instance, the latest advancements have resulted in machinery that boasts up to 30% higher throughput compared to previous models. This crucial improvement not only optimizes resource extraction but also minimizes operational costs, making it a pivotal shift for mining operations.

Tip: When selecting a cone crusher bowl for your operation, consider models that integrate advanced materials and designs to enhance durability and performance. Investing in technology that allows for easier maintenance can drastically reduce time spent on repairs.

Moreover, upcoming designs incorporate enhanced features such as adjustable settings for optimal crushing efficiency and advanced monitoring systems that allow real-time analysis of performance metrics. This evolution in design not only promotes greater adaptability but also supports sustainability by ensuring that operations utilize resources more efficiently.

Tip: Always stay updated on new technological trends and consider proactive strategies for integrating these advancements into your operations to stay competitive in the evolving mining landscape.

The advancements in cone crusher bowl technology play a pivotal role in enhancing the longevity and efficiency of mining operations. At the forefront of this evolution are the innovative materials being integrated into the manufacturing of these crucial components. High-performance alloys and composites not only increase durability but also reduce wear and tear, thereby extending the lifespan of the bowl. These materials exhibit superior resistance to abrasion and impact, making them ideal for the harsh environments often encountered in mining processes.

Furthermore, the incorporation of advanced materials significantly optimizes the operational efficiency of cone crushers. By minimizing downtime due to maintenance and replacement of parts, mining companies can achieve higher productivity rates. Enhanced heat resistance and reduced friction through innovative surface coatings also contribute to more efficient crushing operations. As the mining industry adapts to these innovations, the focus on sustainability and reduced operational costs remains paramount, marking a transformative shift in how mining activities are conducted.

| Material Type | Longevity (Hours) | Efficiency (%) | Cost (USD) |

|---|---|---|---|

| High-Strength Steel | 2500 | 85 | 800 |

| Alloy Composite | 3000 | 90 | 1200 |

| High-Performance Ceramics | 4000 | 95 | 1500 |

| Reinforced Plastics | 2000 | 80 | 600 |

| Titanium Alloys | 3500 | 92 | 2000 |

The mining industry is on the brink of a technological revolution, particularly in the efficiency of cone crushers, as showcased at the 2025 China Import and Export Fair. Performance metrics have become a focal point, emphasizing the critical need for increasing throughput and reducing downtime. Recent studies indicate that advanced cone crusher technology can boost operational efficiency by up to 30%, allowing mines to process more material in a shorter timeframe.

One of the most significant trends in cone crusher design is the integration of predictive maintenance tools, which employ IoT sensors to monitor wear and tear in real time. According to a report by the Mining Industry Council, equipment downtime can cost mining operations upwards of $20,000 per hour. By utilizing these innovative technologies, companies can reduce downtime by 25% or more, ensuring that production targets are met without unexpected interruptions. This shift not only enhances profitability but also contributes to a more sustainable mining operation, as it minimizes resource waste and energy consumption in the long run.

The mining industry is undergoing a transformative shift towards sustainability, with eco-friendly innovations at the forefront of cone crusher bowl manufacturing. Recent reports indicate that circular economy practices could reduce industry waste by up to 30% by 2025, promoting a more sustainable approach to resource extraction. Innovations like the use of recycled materials in manufacturing cone crusher bowls not only minimize environmental impact but also enhance performance by providing higher durability and resistance to wear.

Tips: When considering new equipment for your operations, prioritize suppliers that adopt eco-conscious practices. This not only supports the environment but also aligns with global trends towards sustainability, potentially improving your market competitiveness.

Additionally, advancements in technology are paving the way for more energy-efficient processes in cone crusher bowl production. According to a study published by the International Mining Magazine, energy-efficient designs could lower energy consumption in mineral processing by nearly 20% by 2026. Selecting equipment that integrates these innovative technologies is crucial for operations aiming to meet increasing regulatory demands and consumer expectations for sustainability.

Tips: Stay updated on industry reports and studies that highlight energy-efficient practices to make informed decisions for future investments and to ensure compliance with evolving regulations.

This chart illustrates the adoption rates of eco-friendly innovations in cone crusher bowl manufacturing from 2021 to 2025. The data reflects a significant increase in sustainable practices within the mining industry, emphasizing the shift towards greener technologies.

The mining industry in China is set to experience significant growth in cone crusher technology by 2025, driven by emerging trends in equipment design and functionality. As the demand for efficient and high-capacity mining machinery increases, innovative developments in cone crusher bowl technology are pivotal. These advancements not only enhance performance but also improve sustainability within operations, aligning with global trends toward environmentally conscious mining practices.

The projected growth in China's cone crusher market reflects a broader shift. With an anticipated compound annual growth rate (CAGR) that illustrates strong market confidence, companies are focusing on optimizing their production processes and reducing operational costs. This transition is particularly crucial given the competitive nature of the mining sector.

Tips for staying ahead in the evolving market include investing in the latest technology to boost productivity and performance. It’s essential for organizations to prioritize research and development, ensuring they adopt innovations that cater to future demands. Additionally, maintaining a close watch on market trends can provide valuable insights into competitors and consumer needs, allowing businesses to adapt proactively.