-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Gyratory Crusher Wear Parts play a crucial role in the efficiency and longevity of mining operations. According to a report by Market Research Future, the global gyratory crusher market is projected to grow significantly, reaching a valuation of $5 billion by 2026. These wear parts are essential for maintaining optimal performance amidst the harsh conditions of crushing ores and rocks.

Expert insights reveal the importance of these components. James Thornton, a leading metallurgical engineer, states, "Quality wear parts are vital for minimizing downtime and maximizing production efficiency." This perspective highlights the direct impact of wear part quality on operational success. However, many operations still overlook the consequences of inadequate maintenance and replacement.

The factors influencing wear rates include material properties and operational conditions. Variables can lead to inconsistencies that might hinder machinery performance. Understanding these dynamics is key to enhancing productivity. As industries strive for advancement, investing in quality Gyratory Crusher Wear Parts becomes not just important, but critical.

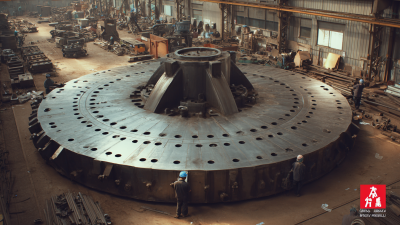

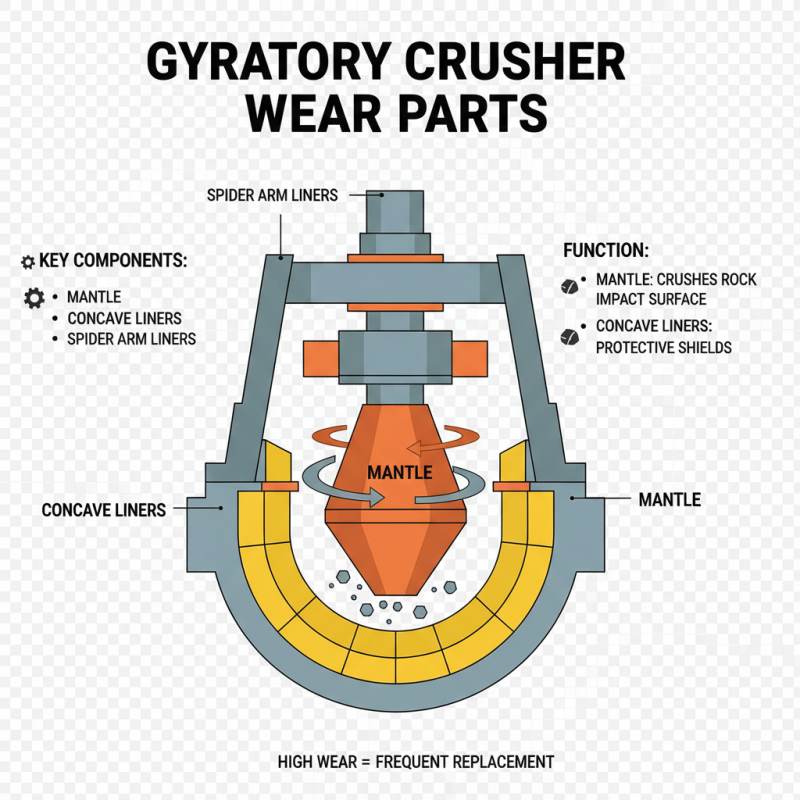

Gyratory crusher wear parts are crucial components in the mining and aggregate industries. These parts include the mantle, concave liners, and spider arm liners. Each piece plays a significant role in the crushing process. The mantle, for instance, is the part that actually crushes the rock. As it rotates, it crushes material against the concave liners. This continuous impact wears down both components over time.

The importance of wear parts cannot be underestimated. They ensure optimal performance and maximum efficiency of the crusher. When wear parts become worn, they can lead to reduced crushing effectiveness. This can result in increased operational costs. It can also cause delays in production. Regular inspection and timely replacement are key to maintaining efficiency. Many operators overlook this aspect. As a consequence, they face unexpected breakdowns and costly repairs. It serves as a reminder to keep a close eye on wear parts. Proper maintenance can prevent inefficiencies and prolong equipment life.

Gyratory crushers are essential in the mining and construction sectors. Their efficiency reduces material size for further processing. The wear parts play a crucial role in the performance and longevity of these machines. Understanding their types helps in maintaining optimal functionality.

One main type of wear part is the mantle. It sits atop the crushing chamber and directly impacts how materials break down. Over time, it wears down due to the friction and forces exerted by the crushed material. Regular replacement is crucial since a worn mantle leads to inefficient crushing. According to industry reports, maintaining proper mantle condition can enhance throughput by up to 15%.

Another vital wear part is the concave surface. It forms the lower part of the crushing chamber, interacting closely with the mantle. If the concave becomes too worn, it can lead to excessive vibrations and uneven material flow. This can decrease production efficiency. Some estimates suggest that unaddressed wear can lead to a 20% drop in processing capacity over time. Neglecting these components can lead to costly downtime and repairs. Regular inspections and timely replacements are imperative for optimal performance.

Gyratory crushers are crucial in mining and aggregate processing. Their wear parts play a vital role in maintaining efficiency and reliability. These components, including mantles and concaves, undergo immense stress. Over time, they wear down and must be replaced to ensure optimal performance.

The importance of wear parts cannot be overstated. They directly affect the crusher's output and energy consumption. If wear parts are not properly maintained, efficiency drops significantly. This can lead to increased operational costs and lower productivity. Operators may overlook wear indicators, risking severe damage to the equipment. In a tough environment, this oversight can have dire consequences.

Regular inspections can help detect wear early. Scheduling replacement parts proactively can prevent unexpected breakdowns. It's easy to underestimate the role of wear parts, but neglect can be costly. Every component counts in the long run, impacting the overall health of the operation. Balancing cost and performance is a challenge that requires constant attention.

The wear parts in gyratory crushers play a critical role in maintaining the efficiency and performance of the equipment. This chart illustrates the common wear parts and their respective replacement frequency based on usage.

Gyratory crushers are essential in mining and aggregate industries. Their wear parts play a critical role in overall performance. These components, like liners and mantles, are designed to withstand extreme conditions. They bear the brunt of crushing forces, absorbing impact and wear.

When wear parts deteriorate, efficiency drops. This can lead to increased operational costs. Replacing worn parts is vital for maintaining optimal performance. A poorly maintained crusher may produce inconsistent material sizes. This inconsistency can affect downstream processes and product quality.

Over time, operators may overlook subtle signs of wear. This can result in costly downtime. Regular inspections help catch issues early. Monitoring wear part conditions ensures that equipment runs smoothly. Awareness of wear part health can significantly impact productivity. It's a simple yet often neglected aspect of crusher maintenance.

Maintaining gyratory crusher wear parts is crucial for optimal performance. These components face intense pressure and abrasive materials, leading to wear over time. Regular inspections can help identify early signs of damage. Ignoring these signs can lead to costly downtime. Simple checks can make a big difference.

Using appropriate lubrication is essential. It reduces friction and prolongs the life of wear parts. However, over-lubricating can attract dirt. This dirt can grind against parts, leading to increased wear. A balance is necessary. Periodic cleaning of components also helps maintain their integrity.

Monitoring the conditions under which the crusher operates is important. Factors like temperature and humidity can affect wear rates. Maintaining the right settings and feed size can minimize unnecessary stress on the parts. Learning from past failures can guide future maintenance. Reflecting on what went wrong helps create a proactive maintenance plan.