-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

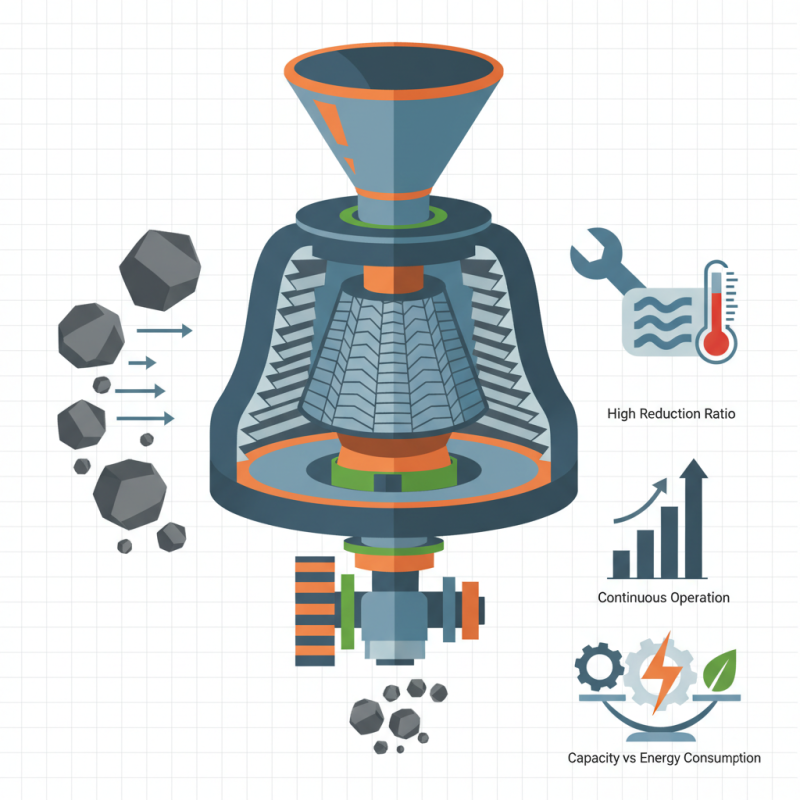

A Gyratory Crusher is a vital machine in the mining industry. It plays a crucial role in breaking down large materials. This equipment crushes rocks using a conical shape. The unique design allows for continuous operation. As the cone moves, it creates forceful impacts.

Understanding how a Gyratory Crusher works is essential for efficient processing. It achieves a high level of reduction in size. Yet, maintenance is critical, and issues can arise without proper care. For example, cooling systems may fail if not monitored regularly. This can lead to operational failures.

There are many applications for a Gyratory Crusher, from quarrying to mineral processing. Its efficiency can greatly influence project timelines. By optimizing its use, companies can improve productivity. However, one must reflect on the balance between capacity and energy consumption. Ensuring reliable performance is a constant challenge in the industry.

A gyratory crusher is a crushing machine used in mining and aggregate industries. It features a conical shape, allowing it to break down large rocks into manageable sizes. These crushers are designed to handle high capacities, making them essential in operations requiring significant material processing.

The key features of a gyratory crusher include its unique crushing action and high productivity. The conical design allows for continuous material flow and fewer bottlenecks. According to industry reports, gyratory crushers can process up to 3,000 tons of material per hour. This efficiency is crucial for large-scale projects. However, maintenance can be challenging, and issues may arise if not addressed timely.

The energy consumption of gyratory crushers can also be a concern. They typically require more power than jaw crushers for the same output. Understanding this aspect is vital for cost-effective operations. Regular monitoring can mitigate unexpected downtimes. In reality, many facilities do struggle with operational inefficiencies. Balancing high output with energy conservation remains a topic of discussion in the industry.

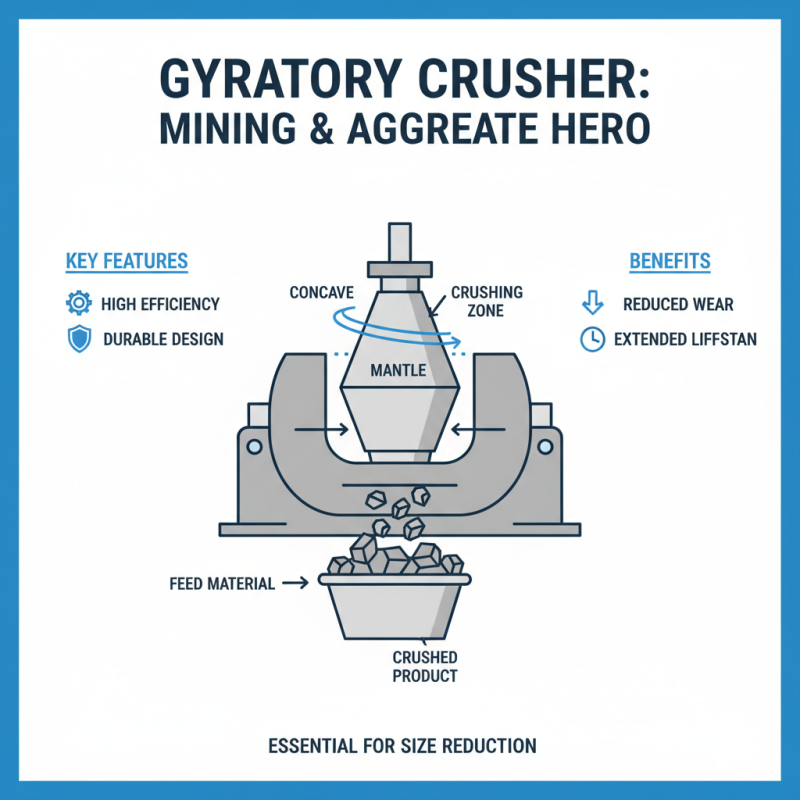

Gyratory crushers play a crucial role in the mining and aggregate industries. Their design focuses on efficiency and durability. A gyratory crusher consists of a cone-shaped mantle that rotates within a concave bowl. This unique design enables it to crush materials effectively. The crushing action occurs as the mantle oscillates, exerting force on the materials. This method reduces wear and enhances the lifespan of the equipment.

In terms of engineering, the capacity of modern gyratory crushers can reach up to 3,000 tons per hour. The size of the feed opening is pivotal for efficiency. Typically, feed openings range from 30 inches to over 60 inches. However, operational challenges can arise. Issues such as clogging and uneven wear are common. It's vital to monitor equipment regularly to mitigate these issues.

Tips:

Ensure to adjust the settings frequently. This helps maintain consistent output. Regular inspections can prevent costly downtime. Consider using advanced monitoring technologies for real-time data. Accurate data helps in making better operational decisions. Investing in training for personnel is equally important. Knowledgeable operators can optimize performance and minimize errors.

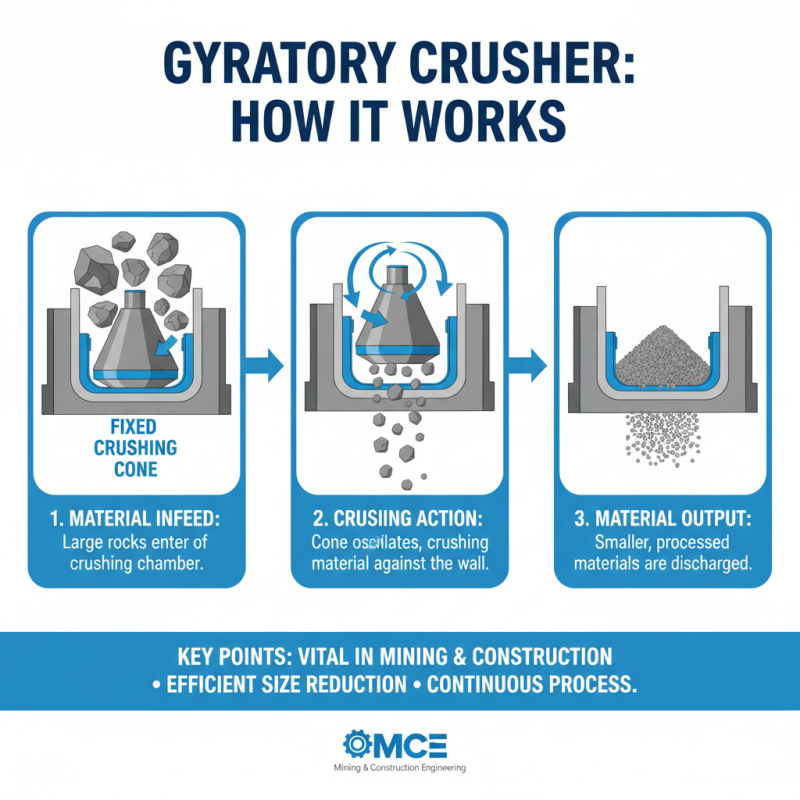

Gyratory crushers are vital in the mining and construction industries. These machines break down larger materials into smaller pieces. The operating principle is straightforward, yet complex in execution. A cone-shaped head crushes materials against a fixed outer wall. This process creates a repeated crushing action, allowing for efficient material breakdown.

During operation, materials enter through the top and fall into the crushing zone. As the head rotates, it compresses the materials. This compression force helps break the stone into desired sizes. Operators must monitor various factors, like the size of the material entering and the crushing speed. If the material is too large, it can lead to inefficiencies. A build-up of processed material can also hinder performance, requiring regular checks.

Additionally, wear and tear on the crushing surfaces is inevitable. Regular maintenance is crucial to keep the machine operational. Over time, components can wear out, affecting the overall efficiency of the crusher. Operators often need to reflect on the performance metrics. Continuous improvement helps maximize production while reducing costs.

Gyratory crushers are essential in the mining and aggregate industries. Their ability to handle large volumes makes them valuable for crushing heavy materials. Capacity is a key performance metric for these machines. They can process tonnes of material per hour, depending on the design and the material's characteristics. This high capacity can boost production, but it requires careful management to avoid operational pitfalls.

Efficiency is another critical metric. A well-functioning gyratory crusher will maximize throughput while minimizing energy consumption. Factors such as the machine's design, maintenance, and the raw material's nature can affect efficiency. Poorly maintained equipment can lead to significant energy losses. Operators must regularly check wear parts and calibration.

In terms of industry applications, gyratory crushers are prominent in mining and construction. They crush ore, rock, and gravel for further processing. However, not every application is suited to this type of crusher. Some materials can cause excessive wear, leading to increased downtime. Each use case may reveal insights into optimizing performance. Understanding these details helps improve operations and adapt to changing material properties.

Gyratory crushers are vital in mining and construction. However, safety and maintenance are crucial for optimal performance. Regular inspection is essential. Check for wear on components. A worn spider arm, for example, could lead to significant issues.

Daily checks are important. Operators should ensure that emergency shut-off systems work well. Safety equipment should be readily accessible. An effective maintenance schedule can prevent breakdowns. It’s also wise to train staff in hazard awareness. Communication on site can reduce accidents.

Maintenance can be overlooked, which may lead to costly repairs. Simple tasks, like cleaning, are often ignored. Dust can accumulate and affect performance. An unclean machine can overheat and become inefficient. Scheduling downtime for thorough cleaning is a good practice. Regular updates to safety protocols are necessary. This ensures that all team members stay informed.