-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

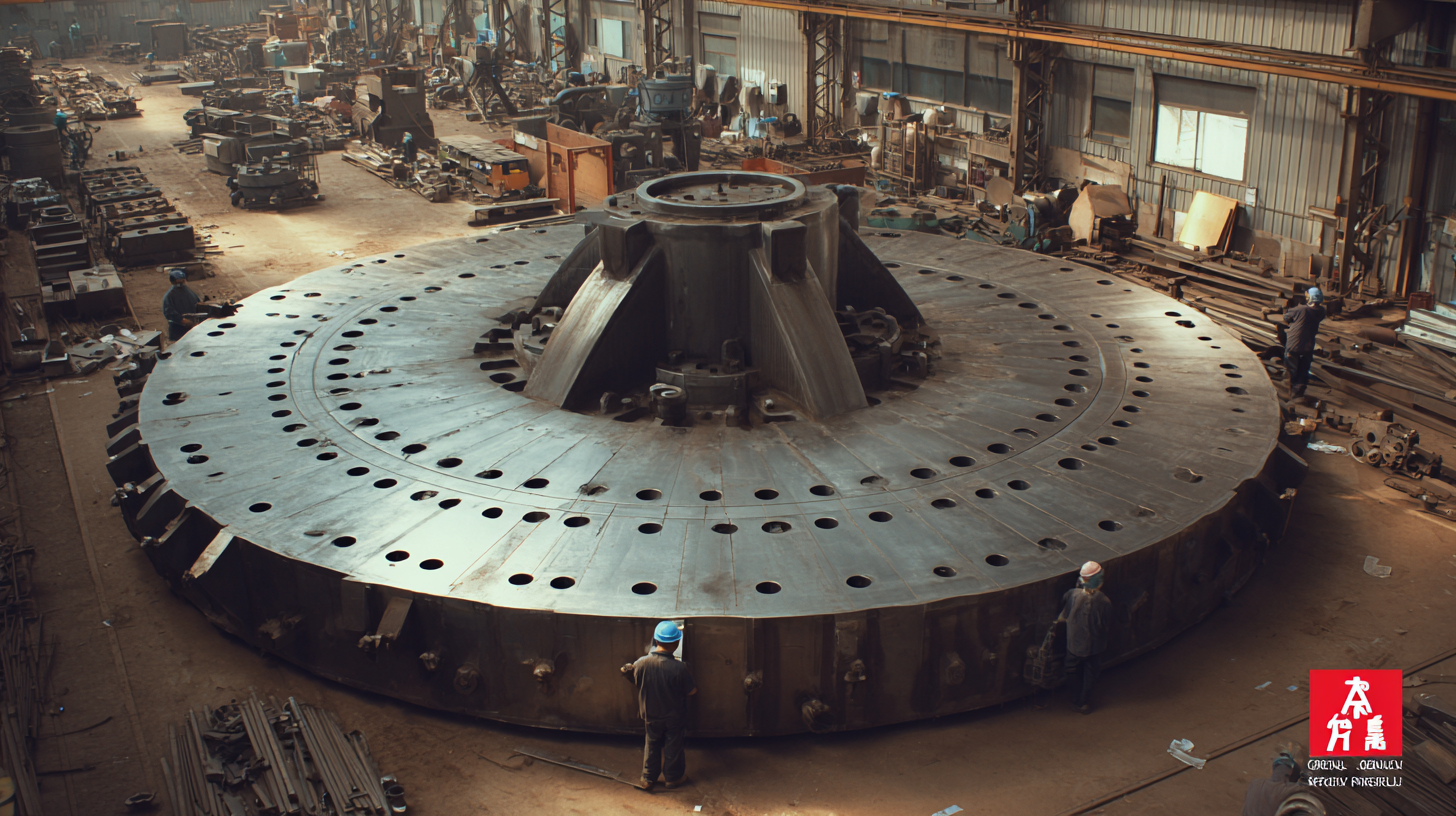

In the ever-evolving mining and aggregate industries, the demand for high-quality Gyratory Crusher Wear Parts has surged, driven by the need for improved efficiency and longevity in crushing operations. According to a recent report by Market Research Future, the global gyratory crusher market is projected to witness substantial growth, reaching approximately $4.1 billion by 2026, fueled by increased investment in infrastructure and mining activities worldwide. As the backbone of crushing operations, the reliability of wear parts directly influences productivity and operational costs, making the selection of superior components critical. Consequently, sourcing Gyratory Crusher Wear Parts from reputable manufacturers in China has become a strategic choice for many companies seeking cost-effective solutions without compromising on quality. This blog will explore the various aspects of choosing the best wear parts and highlight the unmatched quality offered by Chinese suppliers in meeting global demands.

When it comes to enhancing the performance of gyratory crushers, the selection of wear parts plays a crucial role. Gyratory crusher wear parts, designed specifically to withstand the intense impact and abrasive forces found in crushing operations, can significantly improve the efficiency and longevity of the equipment. These high-quality components ensure optimal fit and functionality, reducing the need for frequent replacements and minimizing downtime.

Moreover, utilizing top-tier wear parts can lead to operational cost savings. By enhancing the crusher's performance, facilities can achieve better material throughput and reduce energy consumption. This increased efficiency not only boosts productivity but also aligns with sustainable practices by optimizing resource usage. Investing in premium gyratory crusher wear parts from reliable suppliers becomes a strategic decision that positively impacts both the bottom line and the environment.

| Part Type | Material | Hardness (HRC) | Wear Resistance | Application |

|---|---|---|---|---|

| Mantle | High Manganese Steel | HRC 14-19 | Excellent | Primary Crushing |

| Concave | High Manganese Steel | HRC 14-19 | Excellent | Primary Crushing |

| Spider Cap | Chrome Moly Steel | HRC 28-32 | High | Support Structure |

| Jaw Plate | Ultra High Manganese Steel | HRC 18-22 | Very High | Crushing Chamber |

| Feed Distributor | Carbon Steel | HRC 30-34 | Moderate | Material Feeding |

Chinese manufacturers have gained a strong foothold in the global market for

gyratory crusher wear parts, thanks to several key features that

distinguish their products from competitors. One of the primary advantages is the

high-quality materials used in production. Recent industry

reports indicate that Chinese wear parts are made using advanced alloy compositions, resulting in

enhanced wear resistance and durability. This improvement can extend service life by

30-50%, significantly reducing the frequency of replacements and downtime.

Additionally, the precision engineering and strict quality control processes adopted by Chinese

manufacturers ensure that their gyratory crusher wear parts provide optimal fit and performance.

According to a market analysis conducted by TechSci Research, the global demand for

high-performance crusher components is projected to increase by 7.2%

annually through 2025. As such, investing in quality wear parts from China is not

only a cost-effective solution but also a means to improve operational efficiency.

Tip: When sourcing gyratory crusher wear parts, always check for industry

certifications and customer testimonials. This can help ensure that you're choosing products

that meet recognized quality standards and have a proven track record of performance.

Additionally, consider parts with extended warranties, as they often indicate confidence in

product durability and performance.

The global demand for gyratory crusher components has seen a remarkable surge in recent years, driven by the rapid expansion of the mining and construction industries. Gyratory crushers, known for their ability to handle large volumes of material efficiently, require high-quality wear parts to maintain optimal performance and longevity. As these industries grow, so does the need for reliable suppliers who can provide top-tier components that meet international standards.

Many companies are turning to China for their gyratory crusher wear parts due to the blend of cost-effectiveness and superior manufacturing standards. Chinese manufacturers have honed their production processes to deliver parts that not only fit a variety of brands but also exhibit excellent wear resistance, extending the life of the machinery. This alignment of quality and affordability positions Chinese suppliers as the go-to sources for mining and construction companies around the globe, fulfilling the ever-increasing demands of this vital sector.

When it comes to crushing and processing materials, gyratory crushers stand out for their robust design and efficiency. Unlike other crusher types, such as jaw and cone crushers, gyratory crushers utilize a unique crushing mechanism. The conical head and the stationary outer shell create a higher degree of crushing compared to other types, resulting in better particle size distribution and a reduced need for secondary crushing. This design enables them to handle larger capacities, making them ideal for mining and heavy-duty operations.

Another critical aspect of gyratory crushers is their durability and maintenance requirements. While jaw and cone crushers may require frequent maintenance and part replacements due to their more complex mechanical structure, gyratory crushers often have fewer wear parts. This not only extends the lifespan of the equipment but also reduces operational downtime, enhancing productivity. With global demand rising, particularly in mineral processing industries, selecting high-quality gyratory crusher wear parts from reliable sources, such as reputable manufacturers in China, ensures optimal performance and longevity of this vital equipment.

The quality of gyratory crusher wear parts in China is influenced by several critical factors that manufacturers must consider to meet global demand. Firstly, the choice of raw materials plays a significant role. High-quality steel and alloys are essential for producing durable wear parts that can withstand the harsh conditions of crushing operations. Manufacturers who invest in superior materials will inevitably deliver products that offer better performance and longer service life, which is crucial for clients in various industries.

Another important factor is the production process itself. Advanced manufacturing techniques, such as precision casting and machining, ensure that wear parts are crafted to exact specifications. Quality control measures throughout the manufacturing process help identify defects early, thus maintaining high standards of quality. Additionally, the experience and expertise of the workforce cannot be overlooked; skilled laborers who understand the nuances of production can significantly enhance the overall quality of the parts produced. By prioritizing these factors, Chinese manufacturers can produce unmatched quality gyratory crusher wear parts that cater to global needs.