-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In 2026, the landscape of crushing technology is evolving rapidly. The importance of understanding Jaw Crusher Parts cannot be overstated. According to industry expert Dr. Alan Foster, “Knowing the essential components is crucial for optimal performance.” Each part plays a role in efficiency and durability.

The jaw plate, for example, experiences wear over time. A worn plate can lead to decreased output. The toggle and bearing also play vital roles in the crusher’s operation. Frequent maintenance is essential to prolong their lifespan. Yet, many overlook this. Regular checks on these components can prevent costly breakdowns.

Engaging with the anatomy of these machines is not just for operators. Engineers and designers must also prioritize these elements. Each part must be optimal to ensure productivity. Companies often face challenges with outdated parts. Reflecting on these issues can lead to better planning for future upgrades. In a competitive market, focusing on Jaw Crusher Parts can be the key to success.

Jaw crushers are vital in many industries, especially in mining and construction. In 2026, several essential components will define their efficiency. The jaw plate, for example, plays a crucial role in crushing materials. High-quality jaw plates can significantly enhance the performance of a crusher, as studies indicate that wear rates greatly affect productivity.

Moreover, the toggle plate is another critical element. It helps absorb the energy produced during the crushing process. Industry reports highlight that improper toggle plate adjustments can lead to operational inefficiencies. Surprisingly, many operators overlook this simple aspect, impacting overall performance.

The frame of the jaw crusher is fundamental as well. A robust frame ensures stability and durability during operations. However, some manufacturers still cut corners in material choice, prone to fail under stress. Understanding these components and their interdependencies can lead to better maintenance practices and improvements in design. Addressing these shortcomings is essential for optimal function in modern applications.

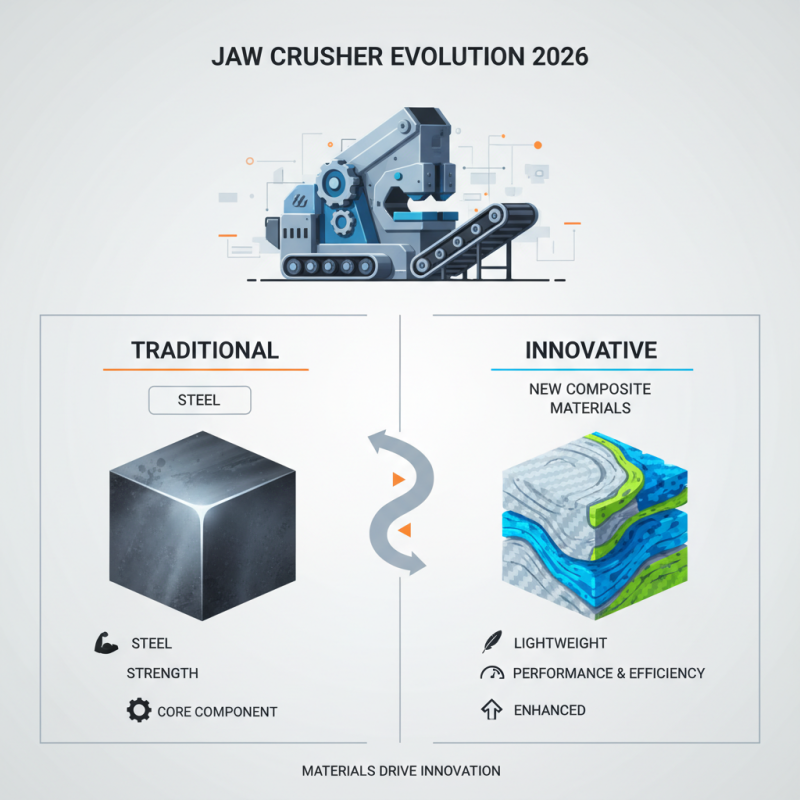

In 2026, the manufacturing of jaw crushers is evolving. Materials play a crucial role in this innovation. Steel remains a core component, known for its strength and durability. However, new composite materials are emerging. They offer lightweight alternatives. These materials can enhance both performance and efficiency.

When considering materials, look for options that resist wear and corrosion. High manganese steel is popular for its toughness. Alternatives like carbides could provide additional longevity. This shift reflects a trend toward improving crusher lifespan and reducing maintenance costs.

Tips: Regularly check the status of your jaw crusher. Understanding material performance helps in making informed upgrades. Don't ignore signs of wear. Early detection can save costs in the long run. Engaging with emerging technologies is key to staying competitive in the industry.

In 2026, jaw crushers are evolving rapidly with significant technological advancements. These developments focus on improving design and functionality. For instance, the integration of artificial intelligence is becoming common. AI systems optimize the crushing process in real-time, enhancing efficiency. A recent market report shows that jaw crusher efficiency can increase by up to 20% with AI implementation.

Understanding the essential components of jaw crushers is vital. Key parts include the jaw plates, pitman, and toggle plate. Recent studies indicate that high-quality materials can extend the lifespan of these components by 25%. However, even with advanced materials, wear and tear are inevitable. Regular inspection and maintenance remain crucial.

Tips: Always monitor noise levels during operation. Unusual sounds can indicate a problem. Additionally, ensure proper lubrication, which prevents unnecessary wear.

As the industry moves forward, the challenge lies in balancing innovation and practicality. Many designs promise enhanced performance but may not fit all operational needs. It's essential to assess whether these advancements truly align with your operational strategies. Is the investment justified? These questions will shape the future of jaw crushers.

The global market for jaw crushers is expected to evolve significantly by 2026. This demand comes from industries such as mining, construction, and recycling. As urbanization continues to rise, the need for efficient crushing equipment increases. Jaw crushers play a vital role in enhancing productivity. They convert large rocks into smaller, manageable pieces.

However, there are challenges in meeting this demand. Supply chain issues, like raw material shortages, may impact production. Manufacturers must navigate these hurdles carefully. The raw material costs can fluctuate, which makes pricing unpredictable. Furthermore, sustainability concerns drive the industry to seek eco-friendly alternatives. This transition might slow down traditional production methods.

The need for innovation is evident. Companies must focus on technology to improve efficiency. Automation in jaw crushers can lead to better performance. Additionally, understanding customer requirements is key. Preferences vary across regions and sectors. Addressing specific needs may lead to better market positioning. Overall, the dynamic nature of the jaw crusher industry calls for constant reassessment and adaptation.

| Component | Material | Function | Estimated Market Share (%) |

|---|---|---|---|

| Jaw Plates | Manganese Steel | Crushing the Material | 30% |

| Frame | Steel | Supports Crushing Mechanism | 20% |

| Toggle Plate | Steel | Adjusts the Size of Jaw Opening | 10% |

| Pitman | Cast Iron | Transfers Energy to the Jaw Plates | 15% |

| Bearing | Steel | Supports Rotational Movement | 5% |

| Drive Mechanism | Variable (Electric/Motor) | Provides Power to Crushing Unit | 20% |

Regular maintenance is crucial for optimal jaw crusher performance in 2026. Inspecting components like jaws and bearings can reveal wear and tear. Keeping the settings adjusted is key to maintaining efficiency. Even slight misalignments can lead to significant drops in productivity.

Operators should develop a strict maintenance schedule. Daily checks can prevent larger issues down the line. Look for unusual noises or vibrations during operation. These symptoms might indicate deeper problems. Cleaning dust and debris from the machine aids efficiency. Neglecting this task often leads to performance dips.

Training personnel on best practices is essential. Skilled workers can identify issues early. However, many may overlook small signs of wear. This oversight can cost time and money. A culture of proactive maintenance can transform operations, leading to fewer breakdowns and smoother processes.