-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

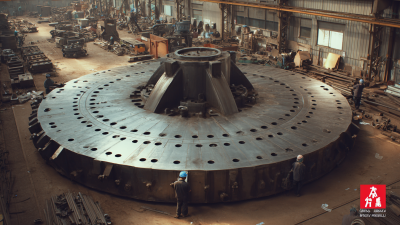

In the mining and aggregate industries, the efficiency and lifespan of machinery are paramount. Among the critical components that influence operational performance are the Gyratory Crusher Wear Parts. These parts are fundamental in ensuring the smooth functioning of gyratory crushers, which are widely used for primary crushing of hard rock and ore materials. However, with constant exposure to abrasive materials and extreme conditions, wear and tear is inevitable.

Consequently, adopting effective strategies for enhancing the longevity of Gyratory Crusher Wear Parts is essential not only for minimizing downtime but also for reducing operational costs. This blog will provide a comprehensive checklist of top strategies to optimize wear parts' durability, enabling operators to maximize their investment and maintain peak performance in their crushing operations. By implementing these practices, companies can significantly extend the life of their equipment, ensuring they achieve sustainability and efficiency in their production processes.

When it comes to enhancing the longevity of gyratory crusher wear parts, material selection plays a pivotal role. Selecting the right materials can significantly impact both performance and durability. High-quality alloys that resist wear and tear are essential for maximizing wear parts' lifespan. Industry studies indicate that using higher manganese content in wear parts can increase durability by up to 20%, allowing crushers to operate more efficiently over extended periods.

Tips: Always consider the type of material being processed and its abrasiveness when selecting wear parts. For instance, softer materials may require different compounds than those that process high-abrasive materials like granite or basalt. Additionally, utilizing high-chrome iron can provide added hardness and wear resistance, making it a preferred choice in many applications.

Another crucial aspect is the hardness of the wear part itself. According to a report by the Mining and Aggregates Research Institute, wear parts with a hardness of over 40 HRC (Rockwell Hardness) can exhibit a significantly longer service life. Therefore, examining the hardness specified by manufacturers is essential to ensure optimal performance and minimal downtime due to part replacements.

Tips: Regularly monitor the wear patterns and adjust your material selection based on real-time performance data. This proactive approach can lead to more informed decisions in selecting and maintaining wear parts, ultimately driving efficiency and productivity in gyratory crushers.

Heat treatment plays a critical role in enhancing the durability of gyratory crusher components. By subjecting metal to controlled heating and cooling processes, manufacturers can significantly alter its microstructure, leading to improved hardness and toughness. This process helps in developing a material that can withstand the high stresses and abrasive conditions typically found in crushing operations. For instance, tempering and hardening treatments can increase the resistance of wear parts, prolonging their lifespan and reducing the frequency of replacements.

Moreover, the significance of proper heat treatment cannot be overstated in the context of wear parts. Inadequate treatment can lead to premature failure, which not only incurs high replacement costs but can also halt production. Advanced techniques such as quenching and carburizing provide a tailored solution to achieve optimal hardness levels while maintaining ductility. As a result, investing in quality heat treatment processes not only enhances the wear resistance of gyratory crusher parts but also maximizes operational efficiency by minimizing downtime and maintenance costs.

| Strategy | Heat Treatment Method | Impact on Durability | Expected Lifespan Increase (%) |

|---|---|---|---|

| Optimized Material Selection | Tempering | Reduces brittleness, enhances toughness | 15-20% |

| Regular Maintenance | Stress Relieving | Minimizes residual stress, prevents cracking | 10-15% |

| Proper Alignment | Hardening | Increases surface hardness, improves wear resistance | 20-30% |

| Controlled Operating Conditions | Annealing | Enhances ductility, reduces hardness | 5-10% |

| Use of Additives | Surface Hardening | Improves surface properties without affecting core | 15-25% |

Optimizing maintenance schedules is crucial for extending the lifespan of gyratory crushers. By implementing a systematic approach to maintenance, operators can significantly reduce downtime and enhance equipment performance. Regular inspections, wear parts assessments, and timely replacements are essential practices. For instance, monitoring the wear rates of specific components can help determine optimal intervals for maintenance activities, thus preventing unexpected failures and extending the operational life of the equipment.

Additionally, leveraging data and technology can further improve maintenance strategies. The integration of predictive maintenance tools can help identify potential issues before they become critical. Operators can also benefit from trends observed in similar equipment, such as the experiences shared from optimizing jaw crushers. By understanding the best practices in equipment size and feed optimization, companies can enhance efficiency and reduce wear on gyratory crusher parts. This proactive focus on maintenance not only prolongs the machinery's longevity but also contributes to cost-efficient operations in the long term.

This chart illustrates the effectiveness of various maintenance strategies in extending the lifespan of gyratory crusher wear parts. The data shows the average increase in wear parts longevity (in months) when specific strategies are implemented.

Advanced coating technologies are revolutionizing the durability and performance of wear parts in gyratory crushers. The increasing integration of High Velocity Oxy-Fuel (HVOF) thermal spray systems is a testament to this evolution, with the global market projected to grow from USD 1.64 billion in 2025 to USD 2.79 billion by 2034, reflecting a robust 7.9% CAGR. These advanced coatings significantly enhance wear resistance, enabling machinery to withstand harsher operational environments while reducing maintenance costs and downtime.

Advanced coating technologies are revolutionizing the durability and performance of wear parts in gyratory crushers. The increasing integration of High Velocity Oxy-Fuel (HVOF) thermal spray systems is a testament to this evolution, with the global market projected to grow from USD 1.64 billion in 2025 to USD 2.79 billion by 2034, reflecting a robust 7.9% CAGR. These advanced coatings significantly enhance wear resistance, enabling machinery to withstand harsher operational environments while reducing maintenance costs and downtime.

Recent innovations in surface coating, such as thin film coatings and plasma electrolytic oxidation (PEO), underscore the critical importance of material science in improving the longevity of wear parts. For instance, studies on interfacial tribological behavior in TiAlN-coated surfaces reveal substantial improvements in wear resistance, particularly under elevated temperatures. Additionally, new waterborne polyurethane coatings have demonstrated remarkable abrasion resistance, indicating that the industry is moving toward more environmentally friendly options without sacrificing performance. As these technologies continue to advance, they pave the way for more resilient and efficient mining machinery, ultimately leading to enhanced operational productivity.

Operating conditions play a pivotal role in the degradation of wear parts for gyratory crushers. According to a report by the Mining Industries Association, up to 40% of wear part failures can be attributed to improper load conditions and material characteristics. Factors such as feed size, moisture content, and the type of materials being crushed significantly influence wear rates. For instance, crushing harder materials can increase wear part wear by as much as 30%, necessitating more frequent replacements and increasing operational costs.

Furthermore, temperature fluctuations and environmental conditions can exacerbate wear part degradation. A study conducted by the International Journal of Mineral Processing revealed that operating temperatures exceeding manufacturer recommendations can lead to premature failure of wear components, often reducing their lifespan by up to 50%. By closely monitoring these operating conditions and implementing data-driven strategies, operators can optimize performance and extend the longevity of their gyratory crusher wear parts. Regular maintenance and adjustments based on real-time feedback can mitigate the effects of adverse operating conditions, enhancing the overall efficiency and cost-effectiveness of the crushing process.