-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The performance of a cone crusher heavily relies on its spare parts. According to industry expert John Smith, "Quality spare parts are vital for optimal performance." This insight emphasizes the importance of using reliable Cone Crusher Spare Parts.

Cone crushers operate under intense conditions. They are subjected to high pressures and constant wear. This makes spare parts fundamental in maintaining the equipment's efficiency. High-quality components can prevent breakdowns and reduce operational costs. However, not all parts are created equal. It's crucial to select parts that meet the specifications of the original equipment manufacturer.

Ignoring the significance of Cone Crusher Spare Parts can lead to performance issues. For instance, using substandard materials can result in premature failures. Reflections on past maintenance experiences show that investing in quality parts pays off. Short-term savings on cheap alternatives may lead to long-term headaches. Ultimately, ensuring that the right spare parts are used is vital for sustained success in operations.

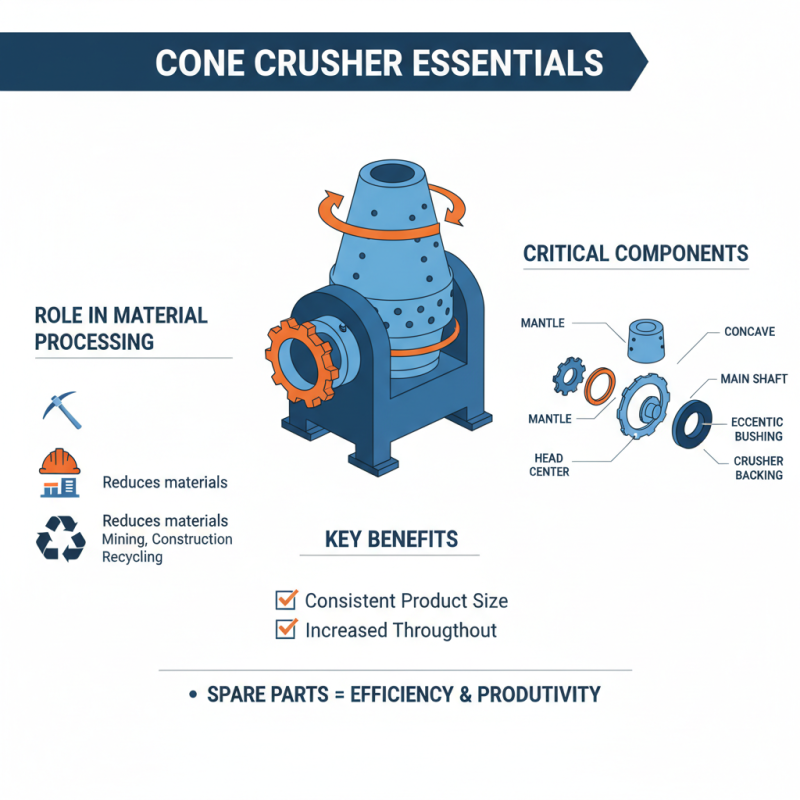

Cone crushers play a critical role in material processing. These machines are designed to crush various materials into smaller, manageable sizes. They are often used in mining, construction, and recycling industries. The efficiency of a cone crusher is greatly influenced by its spare parts. These components are essential for maintaining performance and productivity.

Wear parts, such as liners and mantles, are vital for optimal operation. Over time, these parts can degrade, leading to decreased effectiveness. This wear can result in material not being crushed to the required specifications. Operators may notice a drop in product quality. Regular inspections and timely replacements are necessary to keep the machine functioning well. Ignoring this can lead to significant downtime and costly repairs.

Maintenance is often overlooked, yet it remains crucial. A lack of attention to spare parts can affect the entire production process. Operators must constantly assess the condition of these components. Not doing so can lead to inefficient operations. When spare parts wear out or fail, it can disrupt the entire workflow. Consistent monitoring is key to ensuring long-term performance.

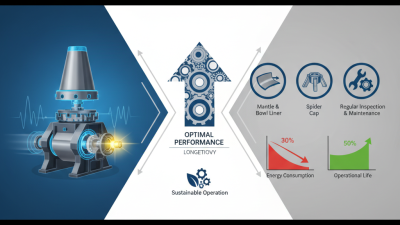

Spare parts play a vital role in the longevity of cone crusher performance. Without them, equipment faces higher risks of breakdown. A report by the Mining Industry Association indicates that wear and tear can reduce overall operational efficiency by up to 35%. Regular maintenance reduces this risk, but spare parts are necessary to sustain optimal performance.

Wear parts, like mantles and bowl liners, can degrade quickly. A proactive approach to replacing these components keeps equipment running smoothly. For example, studies show that replacing worn parts can enhance productivity by an average of 25%. Yet, some operations delay replacements, hoping to save costs. This often leads to unexpected failures and higher spending in repairs.

Investing in quality spare parts is essential. Inconsistent part performance can lead to issues. A detailed inspection of wear components should be standard practice. Statistics show that 70% of equipment failures stem from inadequate maintenance. Addressing this aspect can dramatically extend the lifespan of your machinery.

The quality of spare parts plays a significant role in the performance of cone crushers. When these parts are made with precision and care, the overall efficiency of the crusher improves dramatically. Efficient operation means reduced downtime and increased output. High-quality parts can handle the intense wear and pressure encountered during crushing.

Conversely, inferior spare parts may cause problems. A low-quality component might lead to quick wear and tear. This situation often results in unexpected breakdowns, halting production. Maintenance costs increase as replacements become frequent. Operators need to evaluate their spare parts regularly. A closer look at replacement intervals can prevent significant issues. The right components can make all the difference in reducing operational risks.

Investing in better spare parts is crucial. However, not all companies see this value. Many stick to cheaper options. This choice can lead to setbacks. It’s important to reflect on the long-term impact of this decision. The benefits of quality may outweigh initial savings. Reflecting on past experiences can guide future purchases. Optimal performance requires a commitment to quality.

Cone crushers are vital in the mining and aggregate industries. They crush rock and ore into smaller sizes, enabling easier handling and processing. However, like any machinery, cone crushers require regular maintenance and replacement of spare parts to ensure optimal performance.

Common spare parts for cone crushers include concave liners and mantle. These components endure significant wear during operation. According to industry reports, worn-out liners can lead to reduced efficiency. They may decrease the throughput by up to 30%. Moreover, a lack of proper maintenance can cause excessive downtime, affecting productivity. Regular inspections are essential to identify wear patterns early.

Another crucial spare part is the eccentric bushing. This component helps maintain the precise alignment needed for efficient crushing. A worn eccentric bushing can lead to misalignment and result in increased energy consumption. Statistics show that inefficient crushing processes can raise operational costs by over 20%. Investing in quality spare parts is not just maintenance; it's a strategic move to enhance overall equipment lifespan and efficiency. Regularly replacing these components can significantly improve performance, yet many operators overlook this vital aspect.

Optimizing cone crusher performance hinges on effective maintenance practices. Regular checks of spare parts are crucial. Worn components can lead to improper functioning. This impacts crushing efficiency and increases operational costs. A report by the Mining Industry Council states that proactive maintenance can reduce downtime by up to 30%.

Inspecting your cone crushers routinely helps identify early signs of wear. Proper lubrication is key. It reduces friction and helps avoid overheating. One tip is to monitor oil levels consistently. Inadequate lubrication can significantly shorten the lifespan of crucial parts like the mantle and bowl liner.

Moreover, keep an eye on the settings of your cone crusher. Adjustments ensure optimal size reduction. Poor settings can result in excessive wear, particularly on the liners. A consistent strategy should be in place to track these adjustments. Avoiding this can lead to unexpected performance declines. Remember, the goal is to maintain a balance between throughput and product quality.