-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

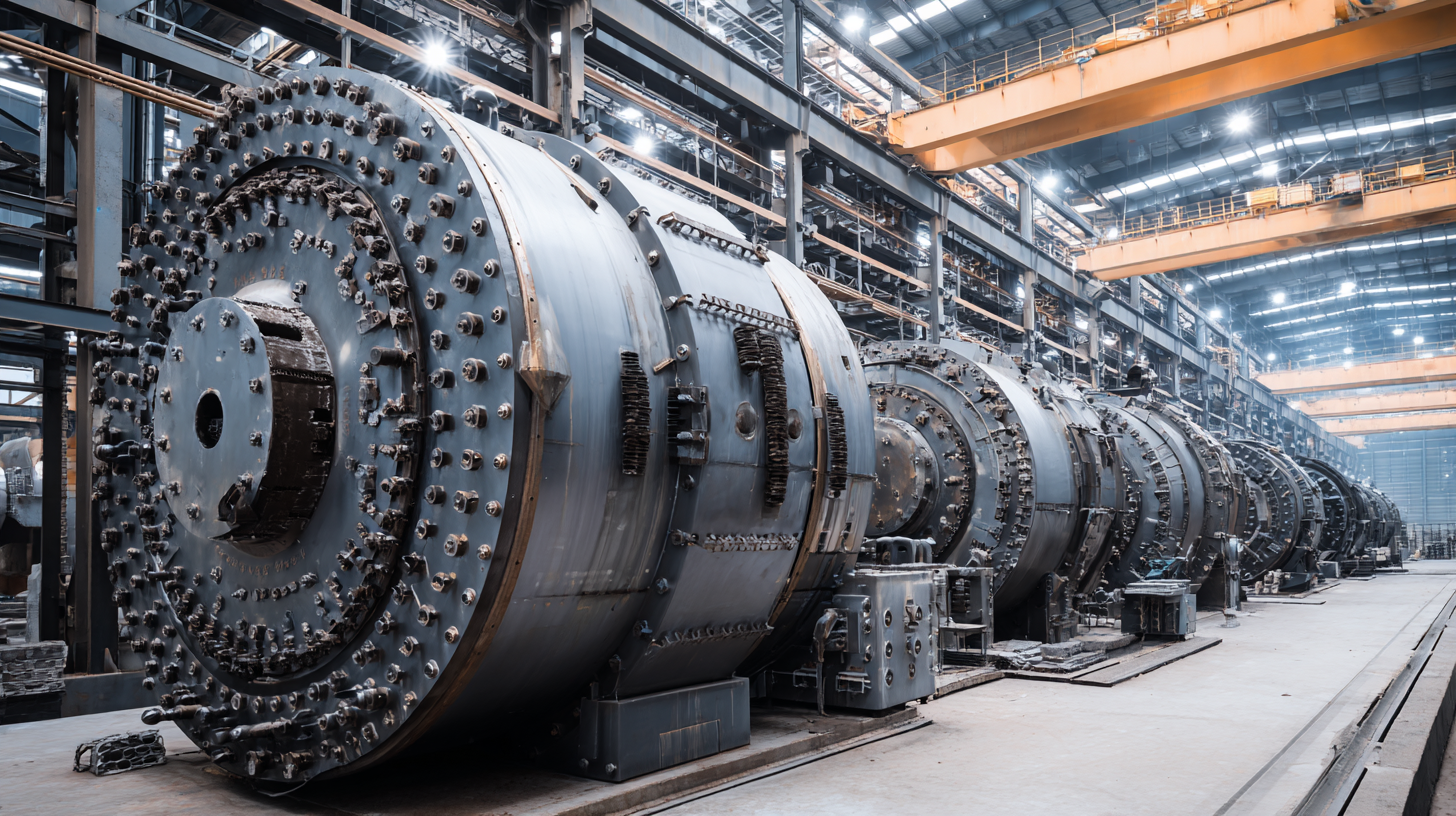

In the world of mineral processing, the efficiency and durability of equipment play a critical role in maximizing productivity and minimizing operational costs. Among the most essential components are the Ball Mill and SAG Mill Liners, which directly impact the performance and lifespan of these grinding systems. Understanding the differences and advantages of various liner designs can help operators make informed decisions that enhance their grinding processes.

This blog delves into an ultimate comparison of the best Ball Mill and SAG Mill Liners, shedding light on their material properties, wear resistance, and performance under varying operational conditions. As we explore these crucial aspects, it becomes evident that selecting the right linings is not just about functionality; it is also about aligning with reliable manufacturers who prioritize quality and innovation.

With "中国优质制造,您的全球合作伙伴" as our guiding principle, we aim to provide valuable insights that empower mining industries to optimize their operations on a global scale.

When it comes to milling processes in mineral processing, understanding the differences between ball mill and SAG mill liners is crucial for maximizing efficiency and performance. Ball mill liners are primarily designed to protect the mill shell from wear while also assisting in ball motion by promoting a cascading action. They are typically made from materials that provide high wear resistance, such as rubber or alloy steel, enabling effective grinding of the ore. The design of ball mill liners can also vary, influencing the speed and intensity of the grinding operation.

On the other hand, SAG mill liners are constructed to handle the larger feed sizes and the higher impact forces typical of semi-autogenous grinding. These liners are often thicker and designed to accommodate the unique grinding action where both the mill’s contents and the media (usually large steel balls) contribute to the milling process. SAG mill liners, therefore, need to withstand not only abrasive wear but also significant impact. The configuration and materials used in SAG liners can dramatically affect the overall milling efficiency and energy consumption, making their performance essential for the success of these operations. Understanding these key differences is vital for selecting the right liner type for each milling process.

This chart compares the performance of Ball Mill Liners and SAG Mill Liners across various dimensions such as Durability, Wear Resistance, Cost Efficiency, Performance, and Maintenance. The data illustrates how each type of liner fares in these critical aspects, providing insights into their suitability for different operational needs.

When selecting linings for ball mills and SAG mills, the material choice plays a pivotal role in determining both performance and durability. High-quality liners not only enhance grinding efficiency but also extend the lifespan of the mill. Typically, liners are made from materials such as rubber, steel, ceramics, or a combination of these. Each material comes with distinct advantages and trade-offs; for instance, rubber liners offer excellent wear resistance and reduced noise, while steel liners provide superior impact resistance and efficient energy transfer.

Tip: Always consider the specific grinding conditions and the material being processed when selecting the liner material, as this can significantly influence overall performance.

Moreover, the design and thickness of the liner can also affect the operational efficiency of the mill. Thicker liners may offer more durability but can also lead to higher energy consumption, while thinner liners might enhance fine grinding but wear out quickly. It's crucial to strike a balance that aligns with your milling requirements and operational goals.

Tip: Regularly monitor the wear patterns of your liners to optimize replacement schedules and select materials that cater to your specific application needs.

Liner wear in grinding mills, particularly in ball mills and SAG mills, is influenced by several critical factors that directly affect the overall efficiency and lifespan of the equipment. According to a report by the International Journal of Minerals Processing, the hardness of the ore and the type of grinding media used play significant roles in the wear rates of liners. For instance, when treating harder ores, wear rates can increase dramatically—often exceeding 0.2 kg/t of processed ore. Additionally, the design of the liner itself, including its material composition and geometry, can lead to variances in wear rates, with rubber liners generally exhibiting lower wear rates compared to steel alternatives.

In the quest for enhanced milling efficiency, optimizing liner design is crucial for both Ball Mills and SAG Mills. Recent studies, such as those published in the International Journal of Mineral Processing, suggest that effective liner configurations can lead to a 10-20% increase in throughput. The materials used, including rubber and composite liners, significantly influence not only wear rates but also the overall energy consumption of the milling process. For instance, rubber liners have demonstrated reduced noise levels and lower ball wear, while composite options can enhance impact resistance and lifespan.

Moreover, advanced liner designs that incorporate finite element analysis (FEA) are proving valuable in predicting liner wear and the resulting impact on mill performance. By adjusting the profile of the liners based on simulations, operators can refine the grinding process and optimize the trajectory of media within the mill. According to a report from the Society for Mining, Metallurgy & Exploration, mills employing tailored liner designs have recorded as much as 15% improvement in energy efficiency, translating to significant cost savings and better material recovery rates. These innovations underline the importance of continual research and development in liner technology for achieving operational excellence in mineral processing.

In the evaluation of liner replacement and maintenance strategies for Ball Mill and SAG Mill operations, cost-effectiveness emerges as a critical factor that can significantly influence overall operational efficiency. Research highlighted in recent industry studies indicates that the total cost of ownership for liner systems can vary greatly, depending on material choice and maintenance protocols. For instance, advanced lightweight materials have been recognized for their potential to not only reduce wear and tear on machinery but also enhance performance longevity, leading to lower replacement costs. Reports suggest that implementing lightweight alloys and high-strength steels in liner construction can result in performance improvements of up to 15% compared to traditional materials.

Furthermore, adopting systematic maintenance strategies not only ensures optimal operational performance but can also minimize downtime and associated costs. A study assessing the economic impact of maintenance across various industries shows that effective maintenance strategies can yield cost savings of 10-25% when comparing routine interventions to reactive repairs. As the industry increasingly shifts towards digital technologies for monitoring wear and tear, the integration of real-time data analytics will further augment the decision-making process about liner maintenance schedules and replacement timing, underscoring the need for continuous innovation in material quality and maintenance approaches to sustain competitive advantages.