-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

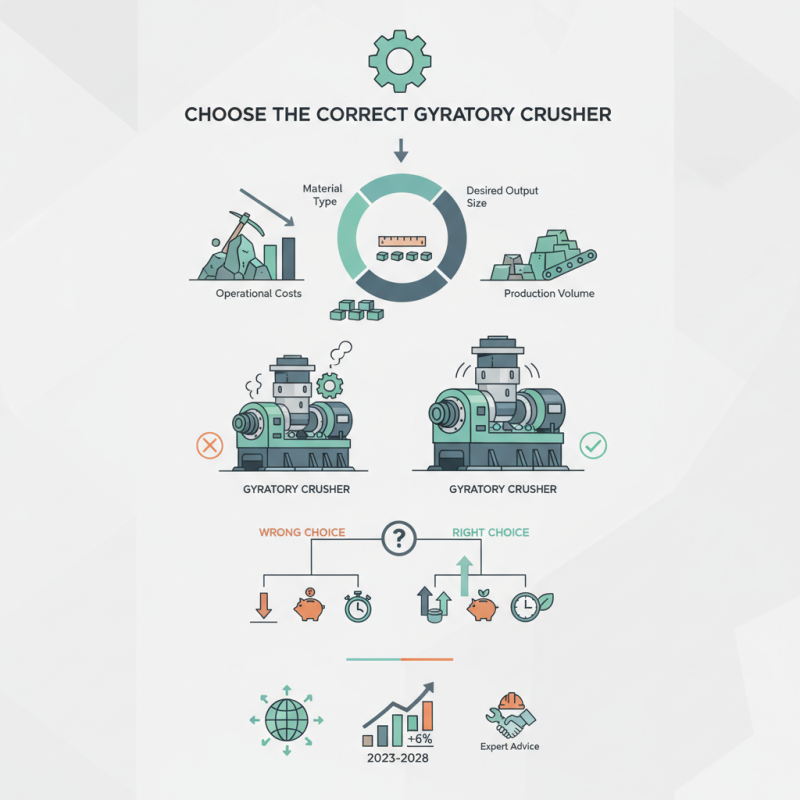

Choosing the right Gyratory Crusher is crucial for maximizing production efficiency and maintaining operational costs. According to a report by the International Journal of Mining Science and Technology, the global market for Gyratory Crushers is expected to grow by 6% annually from 2023 to 2028. With increasing demands for materials in construction and mining, selecting the suitable model is more important than ever.

Expert Paul Smith, a leading consultant in mining equipment, emphasizes, “The right Gyratory Crusher can significantly impact productivity and reduce downtime.” Misjudging your needs could lead to inefficiencies. A poorly chosen crusher may underperform or require frequent maintenance. Factors such as material type, desired output size, and production volume must guide your decision.

Incorporating specific details, like the crusher's capacity and load limits, can refine your selection process. For instance, a crusher designed for high hardness materials needs a robust construction. It’s clear that evaluating these elements requires careful consideration and expert advice. The consequences of a wrong choice can ripple through the entire operation, leading to lost revenue and increased costs.

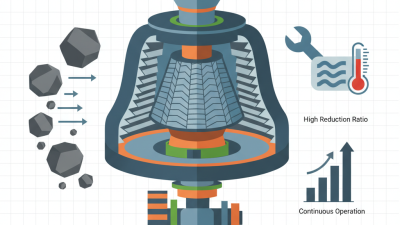

Gyratory crushers are vital in the mining and construction industries. They break down large stones and rocks into manageable sizes. Understanding their function is crucial for selecting the right equipment. These machines use a rotating cone that crushes the material between itself and a stationary outer structure. The design allows for efficient crushing and high throughput.

When considering a gyratory crusher, think about your material type. Are you dealing with hard or soft rock? The hardness affects the crusher's efficiency. You should also evaluate the required output size. Different applications demand various sizes, which will influence your choice. Recognizing your specific needs will lead you to better decisions.

Another critical factor is capacity. Not all operations require the same output. Too much capacity can lead to inefficiency. Conversely, too little may cause bottlenecks. It's essential to balance these elements. Take your time to assess your operation’s unique requirements. This reflective approach can save time and resources in the long run.

When choosing a gyratory crusher, several key factors require careful consideration. The size and capacity of the crusher must align with your production goals. A typical gyratory crusher can handle materials at a rate of 2,500 to 6,000 tons per day. This capacity can directly impact your operational efficiency. Evaluate the hardness and abrasiveness of the material being processed. Harder materials may require heavy-duty models with reinforced structures.

Tips: Analyze your material characteristics before making a decision. It may save you costs.

Another important aspect is the layout of your processing plant. The gyratory crusher's footprint can influence the design of the entire system. If space is limited, consider crushers with a smaller overall size. Take into account the maintenance requirements as well. Some units can be more challenging to service than others, leading to downtime.

Tips: Regular maintenance checks are critical. They can prevent costly breakdowns.

Energy consumption is also vital. Efficient models save both power and operating costs. Reports indicate that improved designs can achieve a reduction of up to 20% in energy use. Balancing initial investment and long-term operational costs is crucial. Make informed decisions for a more effective investment.

When choosing a gyratory crusher, evaluating size and capacity is crucial. Operations often require specific metrics. For instance, the average feed size can range from 0.5 to 1 inch. The capacity typically varies from 150 to 3,000 tons per hour, depending on the model. Assessing your crushing requirements helps in selecting the right unit.

Capacity is not just a number; it needs context. If you consistently demand higher output, you may need multiple crushers. This approach could improve efficiency. However, remember that increasing capacity can lead to higher wear rates. Gyratory crushers may require more frequent maintenance, especially under heavy loads. Always consider these trade-offs.

Tip: Conduct a thorough site analysis before making a decision. Understand your material characteristics. Look at the rock type and hardness. Some materials may challenge even the best crushers. Working with experts can optimize your choice. Balancing capacity with material characteristics ensures you avoid costly mistakes. Your operational needs dictate your equipment choices, so don't rush the process.

When selecting a gyratory crusher, maintenance and support options play a crucial role. Regular maintenance reduces downtime and extends the lifespan of the equipment. According to industry reports, about 30% of a crusher's operating costs come from maintenance activities. Therefore, it is essential to assess the availability of local service centers and the expertise of their technicians.

Training programs can be vital for your staff. Many manufacturers offer training to ensure safe and effective operation. This can lead to fewer incidents and better production efficiency. However, not all training opportunities are created equal. Some may lack depth, leaving operators without a complete understanding. It's important to evaluate these programs carefully.

Additionally, consider the availability of spare parts. Reports indicate that delayed access to parts can increase downtime significantly. A survey revealed that 40% of operators faced equipment challenges due to unavailable components. Investing in suppliers with a robust inventory can mitigate this risk. However, potential over-reliance on any one supplier can create vulnerabilities.

Balancing these aspects is crucial for long-term operational success.

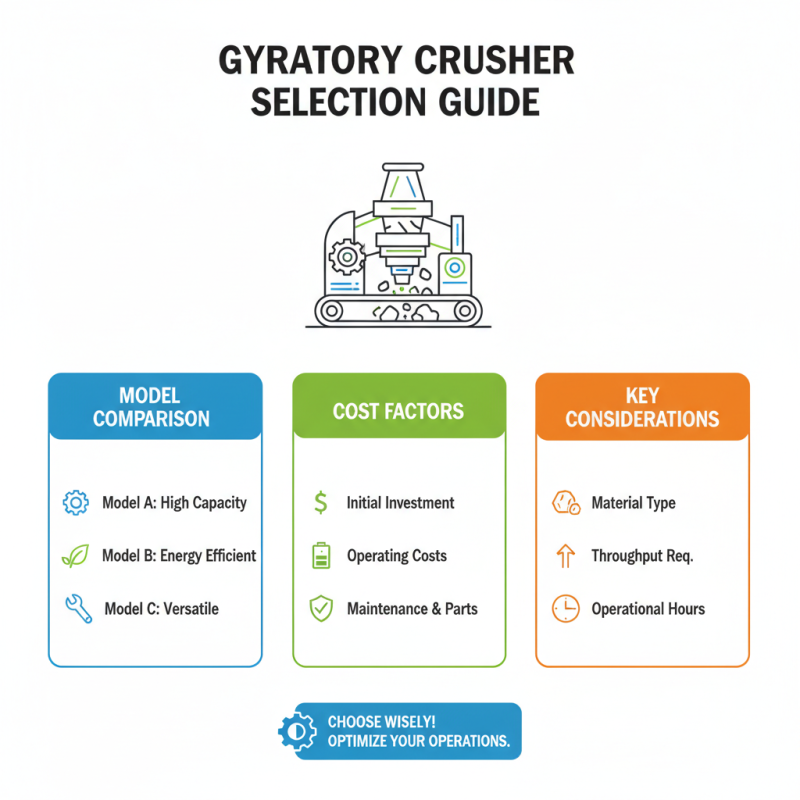

Choosing the right gyratory crusher involves comparing various models and their costs. Each model offers different features that cater to specific operational needs. For instance, some crushers have enhanced crushing capacities, while others focus on energy efficiency. It's essential to assess what matters most for your operations.

When evaluating costs, consider both initial investment and long-term expenses. Some models may appear cheaper upfront but require more maintenance, driving up costs. It's not just about the purchase price. An efficient model can save you money in the long run. However, performance may vary based on material types and project scale.

Don't overlook potential drawbacks. Some crushers may not perform well in certain applications. Conducting trials or simulations can help identify the best fit. It's valuable to reflect on how each model aligns with your project's requirements. Some decisions may lead to unexpected challenges down the line, requiring adjustments to your approach.