-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right Swing Jaw Crusher Plate is critical for operational efficiency. Industry expert John Smith once said, "The right plate can significantly enhance performance and durability." Selecting a suitable plate involves understanding various factors.

Material composition is essential. Plates made from high-quality steel resist wear better. However, selecting the wrong material can lead to premature failure. Additionally, dimensions and design affect how well the plate fits with other components.

It's also important to consider the application. Different mining and crushing operations require specific plate features. Some users may underestimate this aspect, leading to suboptimal performance. Reflecting on these points can help in making a more informed decision. The right Swing Jaw Crusher Plate not only improves productivity but also impacts equipment lifespan.

Choosing the right swing jaw crusher plate is crucial for optimal performance. The swing jaw plays a vital role in determining the efficiency of a crusher. It directly affects the reduction ratio and overall output. A well-designed swing jaw enhances the crushing process, leading to better material handling.

Understanding the materials used in these plates is essential. Stronger materials can withstand high stress while being lightweight. This balance is often hard to find. Sometimes, the choice leans towards durability over weight, which may not always be ideal. Regularly checking for wear and tear is equally important. Neglecting this can lead to performance issues.

Each installation might face unique challenges. For instance, the crushing environment or the type of materials being crushed can differ widely. A one-size-fits-all solution is rarely applicable. An effective choice involves an assessment of specific needs. This requires patience and attention to detail. Knowing when to adjust or change your swing jaw can make all the difference. The right plate contributes to achieving overall operational goals.

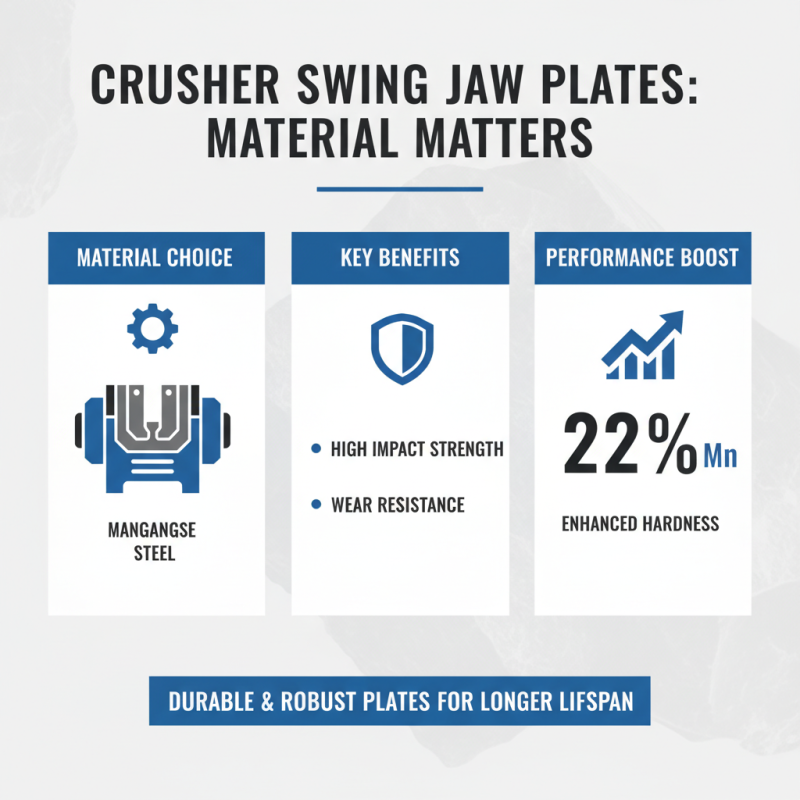

When selecting swing jaw plates for crushers, material choice is crucial. Common materials include manganese steel, which provides high impact strength and resistance to wear. Various industry reports indicate that manganese content can create a durable and robust plate, often with a hardness of up to 22% for enhanced performance.

Other materials, such as alloy steel, offer different benefits. Alloy plates can withstand higher temperatures and provide improved toughness. However, these may not perform as well under abrasive conditions. The key is to match the material characteristics to the specific application needs. According to a study, the right balance between hardness and toughness is essential.

It’s worth noting that not all materials perform equally across different applications. Some may lead to increased operational costs due to faster wear rates. Reports suggest that evaluating performance data and wear patterns can assist in making an informed choice. It is essential to review these aspects on a case-by-case basis and be open to adjustments.

Choosing the right swing jaw plate is crucial for optimal performance in crushing operations. When selecting a swing jaw plate, consider the material it’s made from. High manganese steel is popular due to its excellent wear resistance. However, it can be quite heavy. This weight may affect the overall efficiency of the crusher.

Another factor involves the design of the swing jaw plate. The shape and thickness can significantly influence the crushing process. A thicker plate generally offers more durability but may reduce the speed of crushing. Analyze what suits your needs best. Balancing durability and efficiency can be tricky. Sometimes, a less expensive option may serve just as well as a premium one.

Finally, consider the compatibility with your existing equipment. Sometimes, a compatible swing jaw plate may not be the most durable option. It’s a compromise that needs careful thought. Inadequate attention to these details can lead to increased downtime and maintenance issues. Reflect on your specific requirements before making a decision.

Choosing the right swing jaw plate is crucial for crusher efficiency. Different types of swing jaw plates have unique characteristics. These differences can impact performance and operational costs.

Some swing jaw plates have a smooth surface. This design allows for smoother material flow. Others have a corrugated surface. The corrugated design enhances grip on materials. It can lead to better crushing effectiveness. However, the wear rate may be higher with corrugated plates.

Consider the material being crushed. Harder materials may require more durable plates. Conversely, softer materials can benefit from less aggressive designs. Analyze the specific conditions of your operation. A poorly chosen plate can lead to increased downtime. It’s vital to reflect on performance metrics regularly. Adjustments may be necessary as operational needs evolve.

Swing jaw plates play a vital role in the function of a jaw crusher. Maintaining them properly can extend their lifespan significantly. Regular inspections are essential. Look for signs of wear, cracks, or deformation. These issues often lead to larger problems if ignored. Ensure your inspection routine is thorough. Clean the plates regularly to remove built-up debris. This simple practice can improve performance.

Lubrication is another key aspect. Grease points shouldn't be overlooked. Without proper lubrication, friction increases, leading to premature wear. It's surprising how many operators forget this step. Additionally, adjust the tension of the swing jaw regularly. Incorrect tension can cause uneven wear over time. Monitor the materials being crushed, as harder materials can wear out plates faster.

It's important to remember that no swing jaw plate lasts forever. Operators must be vigilant. Track the performance data and make adjustments accordingly. If a plate wears unevenly, consider the crushing techniques used. Reflecting on these practices helps prevent costly downtime in the future. Swing jaw plates deserve careful attention for optimal operation.

| Dimension | Material | Weight (kg) | Lifespan (months) | Maintenance Tips |

|---|---|---|---|---|

| 1000 x 800 mm | High Manganese Steel | 1500 | 12 | Regular inspection, lubrication, and adjustment. |

| 1200 x 900 mm | Alloyed Steel | 1800 | 18 | Ensure proper alignment and tension of the jaw plates. |

| 1400 x 1100 mm | Wear-Resistant Steel | 2200 | 24 | Perform regular cleaning and replace worn out parts promptly. |

| 1600 x 1200 mm | High Chromium Steel | 2500 | 30 | Adjust the operating speed and maintain proper feeding practices. |