-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right bowl liner for a cone crusher is crucial for efficiency and longevity. Experts emphasize the importance of proper selection. John Smith, a renowned specialist in the Bowl Liner Cone Crusher industry, once stated, "A well-chosen liner can significantly cut operating costs and extend equipment life."

The bowl liner plays a vital role in determining the performance of a cone crusher. It directly affects the size and shape of the crushed material. An ill-fitting liner can lead to uneven wear and additional costs.

Selecting the appropriate bowl liner requires attention to detail. Factors like material type, hardness, and shape must be considered. Mistakes in selection can result in poor performance. Reflecting on past choices can illuminate how critical this decision is. Each crusher is unique, and a one-size-fits-all approach rarely works.

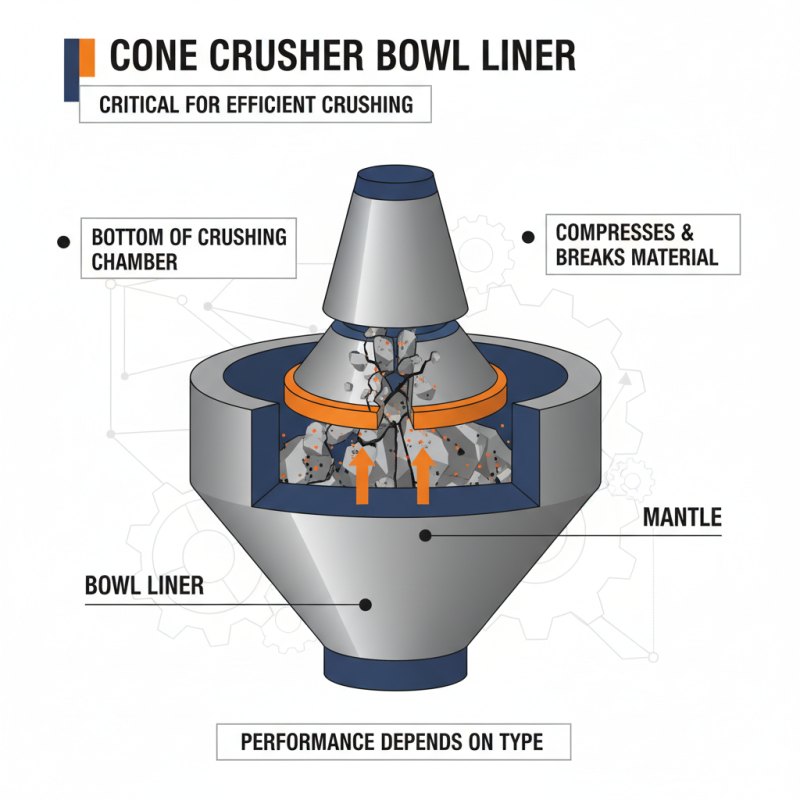

The bowl liner plays a critical role in the functioning of cone crushers. It forms the bottom part of the crushing chamber. With the material placed inside, the bowl liner helps to compress and break it down effectively. This process is essential for achieving the desired size of crushed material. However, the type of bowl liner chosen can greatly affect performance.

There are several factors to consider when selecting a bowl liner. The material composition is important, as it can determine durability and wear resistance. Different applications may require different hardness levels. A softer liner may wear out quickly, leading to frequent replacements. On the other hand, a harder liner may reduce crushing efficiency if it does not conform well to the material being processed.

Careful inspection and monitoring are necessary. Regular maintenance can extend the life of the liner. However, it is common to overlook the condition of the liner until it fails. This can lead to costly downtime. Therefore, understanding how bowl liners function assists operators in making informed decisions. Investing time in selection and maintenance can yield better productivity in the long run.

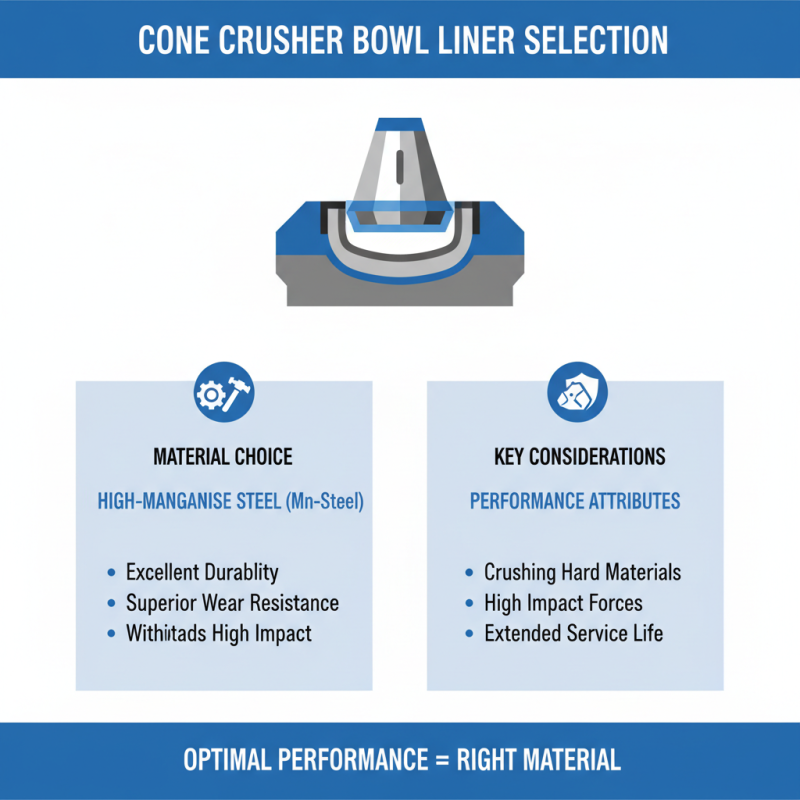

When selecting the right bowl liner for a cone crusher, it is crucial to consider the materials used. Bowl liners are typically made from high manganese steel, which offers excellent durability and wear resistance. This material can withstand high impact forces, making it suitable for crushing hard materials.

Another option is chrome-moly steel, known for its toughness and impact resistance. This alloy provides a balance between hardness and ductility, which is essential for longevity during operations. Some liners also employ special alloys that improve abrasion resistance, contributing further to their wear life.

It's important to reflect on the specific needs of your crushing application. Not every material is perfect for every situation. Sometimes, a specific liner might wear out faster than expected. Assessing the material properties regularly can inform future decisions and enhance productivity. Understanding the trade-offs can lead to a more informed choice. Consider the type of material you're crushing and adapt as necessary.

Choosing the right bowl liner for cone crushers is crucial for efficiency and productivity. Several factors should be considered in this process. One key aspect is the material composition of the bowl liner. High manganese steel is commonly used due to its durability and resilience under high wear conditions.

Another important factor is the profile of the bowl liner. Different profiles can significantly affect the crushing capacity and product shape. According to industry reports, selecting a liner with the optimal profile can improve output by as much as 20%. It's essential to analyze the specific application and the type of material being crushed to choose the best profile.

Tips: Always consult wear studies to understand how different liner compositions perform over time. Also, consider the operating conditions. A bowl liner that performs well in one environment may not do so in another. Frequent monitoring of wear patterns can provide insights for adjustments.

Keep in mind the cost implications of various options. Cheaper materials may seem enticing but can lead to unexpected downtime due to premature wear. Analyzing the total cost of ownership over the lifespan of the liner is crucial. It's a balancing act between initial expenditure and long-term durability. Consider past experiences and consulting with experts in the field for better decision-making.

Choosing the right bowl liner for a cone crusher is crucial. The design and profile significantly impact performance. A well-shaped liner improves material flow and increases output. According to industry studies, proper liner configuration can enhance throughput by 20%. This data highlights the importance of evaluating factors like profile and material type.

Liner profiles range from shallow to deep. A shallow profile may lead to lower material retention time, impacting crushing efficiency. Conversely, a deep profile can enhance material hold but may increase wear rates. Each option has its trade-offs. It’s essential to analyze specific operational conditions when selecting a profile. The goal is to achieve a balance between wear life and production efficiency.

Maintaining effective liner design requires constant evaluation. Regular monitoring of wear patterns can provide insights into performance. Abrasive materials can wear down liners quickly. Some operations overlook this aspect, leading to unexpected downtimes. Suboptimal liner choices often result in reduced output. Thus, reflection on current strategies is vital for maximizing crusher performance and longevity.

Maintaining bowl liners in cone crushers is crucial for operational efficiency. Regular checks can prevent unexpected breakdowns. Inspect the liners frequently for wear and tear. Look for cracks or excessive wear patterns. Addressing minor issues early can save costly repairs later.

Proper lubrication is key. Ensure that the liners are adequately lubricated to reduce friction. This helps prolong their lifespan. Use the right type of lubricant and replace it as needed. Over-greasing can also cause problems. It’s essential to find a balance.

Additionally, monitor the crusher's operating conditions. High-pressure situations can wear down liners faster. Adjust feed rates and monitor material size to minimize strain. Observing these factors will help in extending the life of bowl liners. It’s a continuous process that requires diligence and attention.