-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

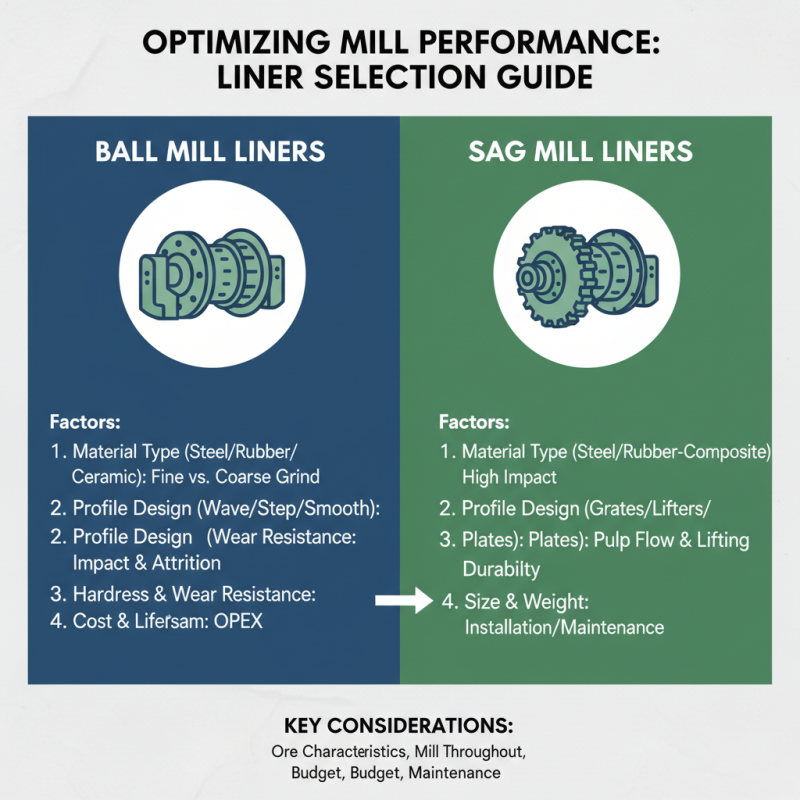

When it comes to mining and mineral processing, choosing the right liners for Ball Mill SAG Mills is critical. According to Dr. John Smith, a leading expert in the field, “Proper liner selection can increase efficiency and reduce maintenance costs.” This highlights the importance of making informed decisions in liner selection.

Ball Mill SAG Mill Liners play a significant role in the performance of milling operations. They provide the necessary protection while optimizing the grinding process. Different materials and designs can impact the lifespan and efficiency of the mills. Therefore, selecting the right type requires careful consideration of various factors.

It's easy to overlook the importance of these components. Many operations may focus on machinery but neglect liner quality. Evaluating wear rates, mill types, and operating conditions is essential. A poor choice can lead to increased downtime and costs. Reflecting on past decisions can improve future selections in these critical areas.

The selection of ball mill and SAG mill liners is crucial in milling processes. These liners protect the mill's shell and enhance the efficiency of grinding. According to a report by the International Journal of Mining Science and Technology, the right liner material can increase grinding efficiency by 10-15%.

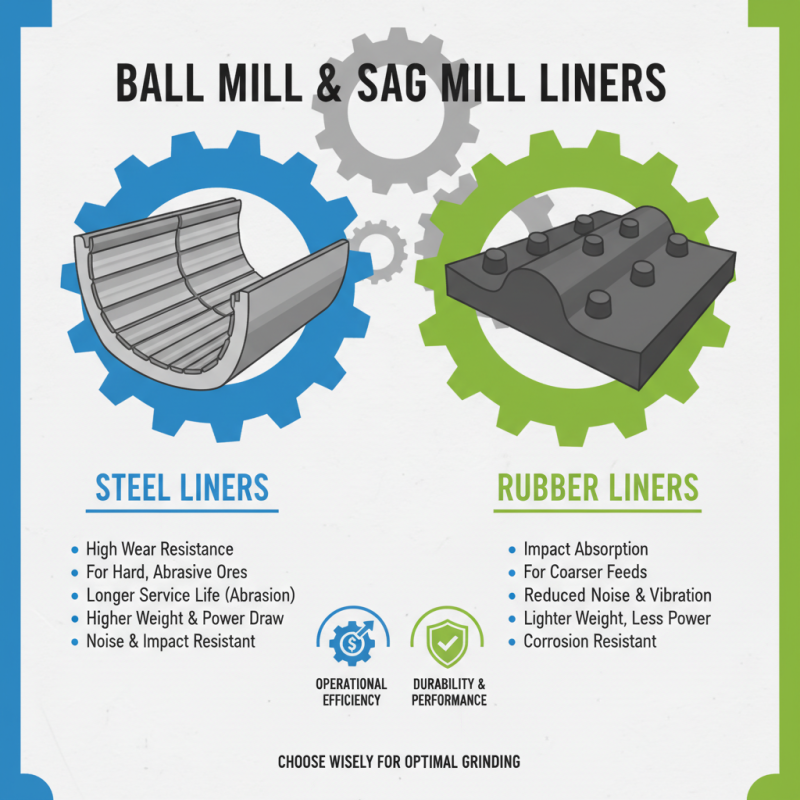

Liners come in various types, like rubber and steel. Rubber liners offer lower service costs and quieter operation. In contrast, steel liners provide superior wear resistance. A study conducted by the Society for Mining, Metallurgy & Exploration found that steel liners could last up to 30% longer than conventional materials based on specific grinding conditions. However, using heavier steel can lead to increased energy consumption, an aspect that needs careful analysis.

Choosing the right liner involves examining several factors. Operational parameters, like mill speed and ore characteristics, play a significant role. A mismatch in the type of liner and the application's needs can lead to premature wear. Performance may drop, leading to increased downtime. In the end, knowing the milling process thoroughly assists in making informed decisions about liner selection.

Choosing the right ball mill and SAG mill liners is crucial. The right choice impacts performance and longevity. Several key factors must be considered when making this decision.

Material type is important. Different materials offer varying wear resistance. For example, rubber liners are lighter and quieter. They can be good for certain applications. However, metal liners are tougher and withstand higher impacts. Understanding the operating conditions of your mill will greatly influence your choice.

The design of the liners matters too. Some have a tongue-and-groove design while others are smooth. Tongue-and-groove designs can aid in secure fitting. This ensures reduced liner movement during operation. Liner thickness can affect the grinding efficiency. Thicker liners can last longer but may alter mill dynamics. Adjusting these factors requires careful consideration. Sometimes, trial and error is part of the process. Reflecting on past experiences can lead to better decisions.

Choosing the right materials for ball mill and SAG mill liners has a significant impact on performance. Various material options exist, each with its own pros and cons. Common materials include rubber, steel, and composite liners. Rubber liners are known for their softer nature, offering lower noise and reduced weight. They can enhance mill efficiency by minimizing wear rates. However, they may not withstand highly abrasive materials as effectively as steel.

Steel liners provide superior durability. They are an excellent choice for applications involving high-impact forces. These liners can handle abrasive particles but may increase operational noise levels. Additionally, they often require more maintenance and are heavier, affecting the mill's overall efficiency. Composite materials blend rubber and steel properties, aiming to optimize performance. They can balance durability and noise reduction but may come at a higher initial cost.

According to a recent industry report from the International Journal of Mining and Mineral Engineering, using the appropriate material can increase liner lifespan by up to 30%. This statistic highlights the importance of understanding the material’s strengths and weaknesses. The choice of liner material should be tailored to the specific operational environment, production goals, and economic factors, making the decision process complex. Each project may require reevaluation and fine-tuning to achieve optimal results.

| Material Type | Pros | Cons | Cost |

|---|---|---|---|

| Steel | High strength and toughness; Good wear resistance | Prone to corrosion; Can be brittle | Moderate |

| Rubber | Excellent impact absorption; Good corrosion resistance | Lower wear resistance; Limited temperature range | Low |

| Composite | Combines benefits of rubber and steel; Lightweight | More expensive; Processing can be complex | High |

| Ceramic | Very high wear resistance; Low friction | Brittle; Expensive to produce | Very high |

| High-Chromium Cast Iron | Excellent hardness and wear resistance; Good impact resistance | Heavy; Can be expensive | High |

When choosing ball mill and SAG mill liners, performance and durability are crucial factors. Different liner designs impact wear resistance and overall operational efficiency. Materials such as rubber and steel offer varying levels of performance. Each type has unique attributes that can affect the grinding process.

Tip: Pay close attention to the wear rates of liners over time. Regular monitoring can save costs in the long run.

Various designs include wave patterns and ribbed structures. Each design affects the movement of balls and the material being processed. The goal is to enhance grinding while reducing energy consumption. It’s important to analyze how each liner design performs under specific conditions.

Tip: Test different liner designs in small-scale trials. This can provide insights into performance before full-scale implementation.

Reflection is key when evaluating liner efficiency. Sometimes, a less popular design could outperform established ones. Collect feedback from operators regularly. Their experience can highlight liner issues that numbers may not reveal.

Choosing the right liners for ball mills and SAG mills is crucial for efficient operation. Regular maintenance and timely replacement can significantly extend the life of these components. According to a recent industry report, poorly maintained liners can lead to a decrease in mill availability by up to 25%. Therefore, understanding when and how to maintain these liners is vital.

To maintain your mill liners, consider a few practical tips.

Inspect liners regularly for signs of wear or damage. Ensure to replace components when the wear reaches a certain threshold, usually around 30% of the original thickness. This proactive approach can help prevent more extensive damage to the mill itself.

Another consideration is the material type. Certain materials, like high-carbon steel or rubber composites, offer different benefits. Analyze the mill's operating conditions and select liners that optimize performance. Remember, even minor wear can lead to inefficiencies, impacting overall productivity. Effective management of liner life can provide significant cost savings in the long term.