-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the dynamic landscape of the mining and aggregate industries, the demand for high-quality components, such as the Swing Jaw Crusher Plate, has reached unprecedented levels. According to a recent report by Market Research Future, the global mining equipment market is projected to surpass $100 billion by 2025, driven by the growing need for efficient and durable machinery. As a critical part of jaw crushers, the Swing Jaw Crusher Plate plays a vital role in ensuring optimal performance and longevity of the equipment. However, sourcing these plates from reliable suppliers can be challenging, especially for international markets. It is essential to identify premier manufacturers in China who excel in delivering unmatched quality and have a proven track record in the industry. This blog will explore essential strategies for finding top-tier suppliers of Swing Jaw Crusher Plates, ensuring that you make informed choices that contribute to the success of your operations.

Swing jaw crusher plates play a crucial role in the mining and quarrying sectors, operating as the primary component in the crushing mechanism. According to a report by Market Research Future, the global mining equipment market is projected to reach approximately $250 billion by 2025, with the demand for high-quality and durable crushing equipment, including swing jaw plates, significantly increasing. These plates are essential for ensuring efficient material size reduction, which directly impacts the overall productivity of mining and quarrying operations.

In terms of material composition, premium swing jaw plates are often made from high manganese steel, which offers excellent hardness and wear resistance. A study from the International Journal of Mining Science and Technology highlights that using wear-resistant materials can extend the lifespan of these plates by over 30%. This improvement not only lowers maintenance costs but also enhances operational efficiency by minimizing downtime. Consequently, investing in high-quality swing jaw crusher plates from leading Chinese manufacturers can provide a competitive advantage in the global market, aligning with the growing emphasis on sustainable and cost-effective mining practices.

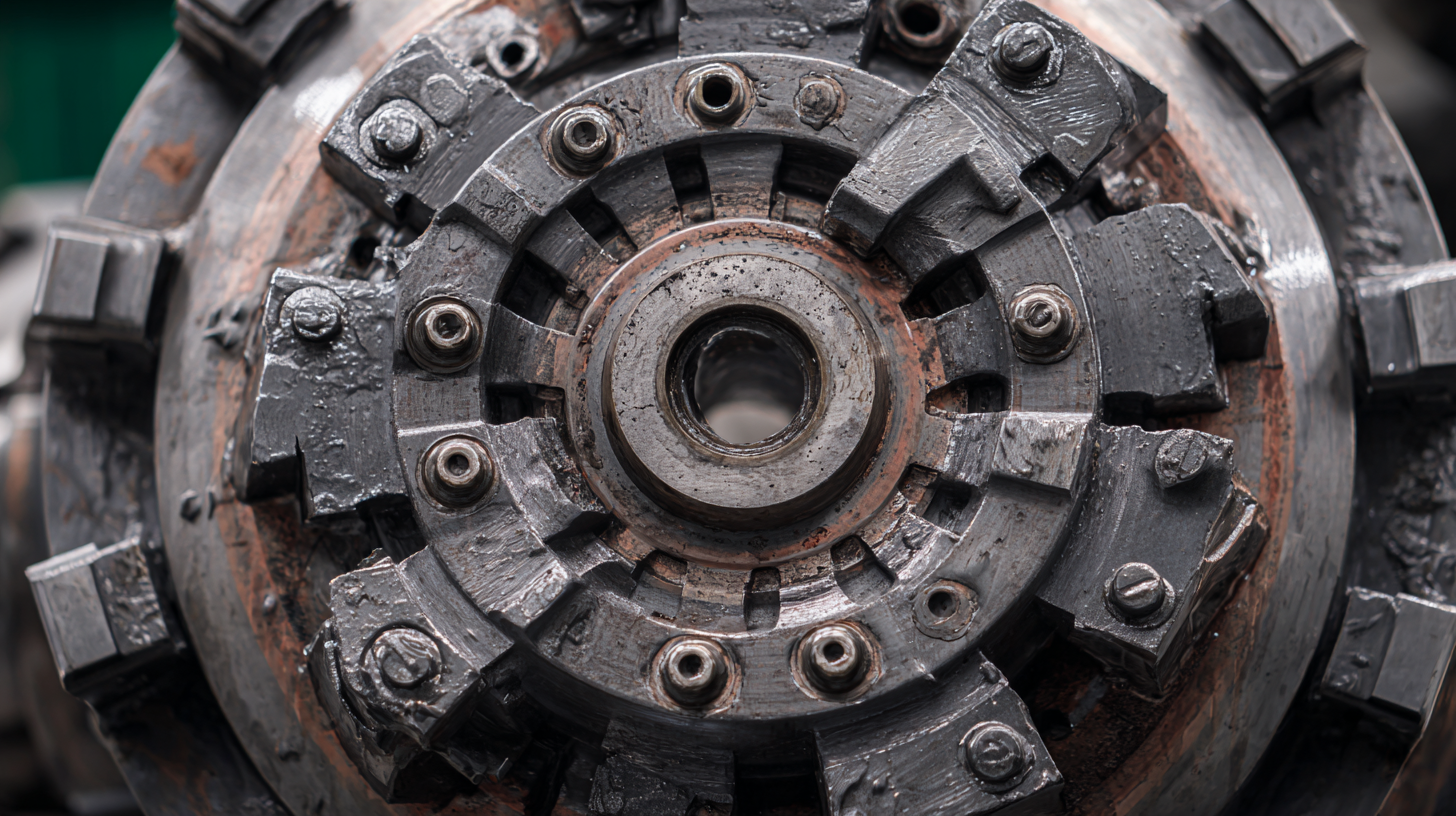

When selecting a high-quality swing jaw crusher plate, several key features should be emphasized to ensure optimal performance in various mining and aggregate applications. First, the material composition plays a crucial role in durability and efficiency. Steel alloys, particularly those with a manganese content of 12-14%, are renowned for their high impact resistance and wear life. According to a report by the International Journal of Minerals, Metallurgy and Materials, a well-designed manganese steel crusher plate can withstand significant stress and offer an extended service life, often exceeding that of standard options by up to 30%.

Another essential feature is the design and fitment of the swing jaw plate. A precise design that aligns with the crusher’s specifications can significantly enhance the crushing process. Studies have shown that poorly fitted plates may lead to misalignments and uneven wear, severely impacting productivity. In fact, the Global Mining Equipment Market Report indicates that equipment misalignments can decrease operational efficiency by nearly 20%. Thus, choosing plates from leading manufacturers known for their meticulous engineering practices ensures optimal compatibility and performance, minimizing downtime and maintenance costs while maximizing output.

When it comes to swing jaw plates, the manufacturing prowess of China stands out prominently. Recent data from industry reports indicate that the market for jaw crushers is expected to expand at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028. This growth is driven largely by the high demand for crushing equipment in sectors such as mining, construction, and recycling. Chinese manufacturers, known for their advanced engineering techniques and cost-effective production, dominate this market segment, producing high-quality swing jaw plates that are critical for operational efficiency.

Among China's top manufacturers, companies like Metso and Sandvik have been leading the charge, consistently investing in R&D to improve the durability and performance of their swing jaw plates. For instance, reports highlight that the tensile strength of jaw plates from these leading firms is often 20% higher than standard offerings, significantly enhancing the lifespan of the equipment. As global demands increase, selecting the best swing jaw plate often comes down to the blend of technology and material quality provided by these manufacturers, ensuring that clients receive unmatched performance tailored to their operational needs.

| Manufacturer | Material Quality | Dimensional Accuracy (mm) | Tensile Strength (MPa) | Average Lifespan (Months) | Price Range (USD) |

|---|---|---|---|---|---|

| Manufacturer A | High Carbon Steel | 1500 ± 5 | 900 | 24 | $150 - $200 |

| Manufacturer B | Alloy Steel | 1490 ± 5 | 950 | 30 | $180 - $230 |

| Manufacturer C | Manganese Steel | 1500 ± 5 | 800 | 18 | $140 - $190 |

| Manufacturer D | Boron Steel | 1505 ± 5 | 920 | 28 | $160 - $210 |

The manufacturing process of durable swing jaw crusher plates is a meticulous endeavor that combines advanced technology with stringent quality control measures. At the forefront of this process is the selection of premium raw materials, often sourced from reputable suppliers. These materials are subjected to rigorous testing to ensure they meet the necessary standards for toughness and wear resistance, crucial qualities for components that operate under significant stress in crushing applications.

The manufacturing process of durable swing jaw crusher plates is a meticulous endeavor that combines advanced technology with stringent quality control measures. At the forefront of this process is the selection of premium raw materials, often sourced from reputable suppliers. These materials are subjected to rigorous testing to ensure they meet the necessary standards for toughness and wear resistance, crucial qualities for components that operate under significant stress in crushing applications.

Once the raw materials are secured, they undergo various processing stages, including casting, forging, and machining. Each stage is closely monitored, with precise specifications followed to achieve the required dimensions and tolerances. Advanced machining techniques, such as CNC machining, are employed to enhance the accuracy of the plates. After initial fabrication, the swing jaw plates are treated with heat treatments to further bolster their strength and durability. Finally, thorough inspections and quality assurance tests are conducted before the plates are shipped to global markets, ensuring that manufacturers deliver only the best products to their customers.

The demand for quality swing jaw crusher plates is on the rise, driven by the expanding stone crusher market. As construction materials become increasingly sought after across various industries, manufacturers are focusing on producing durable and wear-resistant components. This trend not only highlights the need for high-quality crusher plates but also underscores the importance of sourcing these components from reputable suppliers. The wear-resistant steel plate market's projected growth to USD 2.90 billion by 2034 at a CAGR of 5.16% indicates a robust trajectory for manufacturers who prioritize quality and reliability in their products.

In addition, global market dynamics are shifting, with emerging markets tapping into advanced manufacturing capabilities. As nations like Japan explore new mineral reserves, particularly at deep-sea vents, the implications for the materials used in construction equipment and machinery are profound. This demand for innovative solutions in material sourcing amplifies the need for premier manufacturers to meet the evolving expectations of the global infrastructure sector.

Quality swing jaw crusher plates will be pivotal in maintaining efficiency and effectiveness in crushing applications, ensuring that manufacturers are well-positioned for sustained growth in the years ahead.